- HOME

- INDUSTRIES

- DIGITAL MANUFACTURING

- Formlabs

Form Cure L V2: Precise, consistent results — every time

Blazing fast curing for larger SLA parts

- HOME

- INDUSTRIES

- DIGITAL MANUFACTURING

- Formlabs

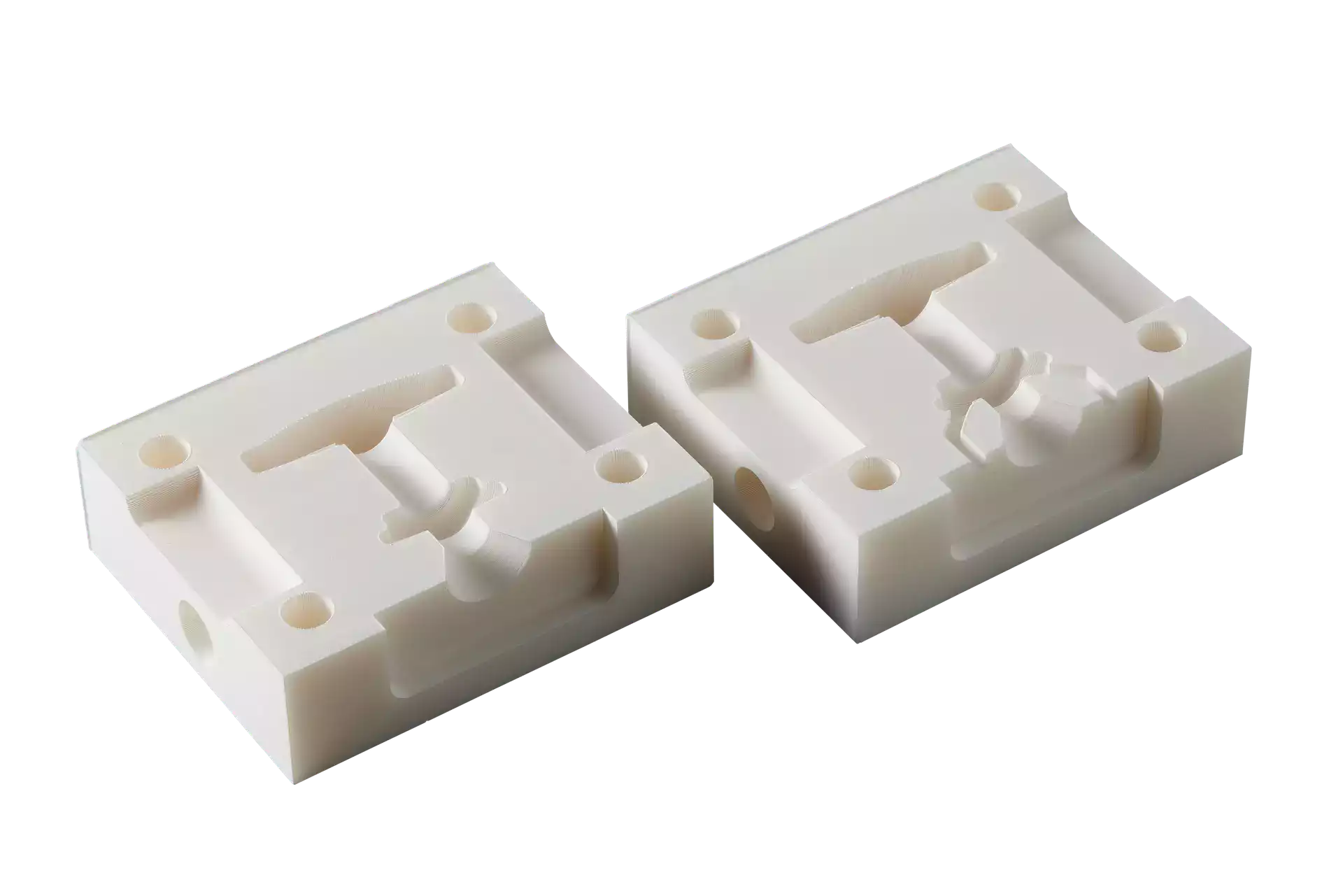

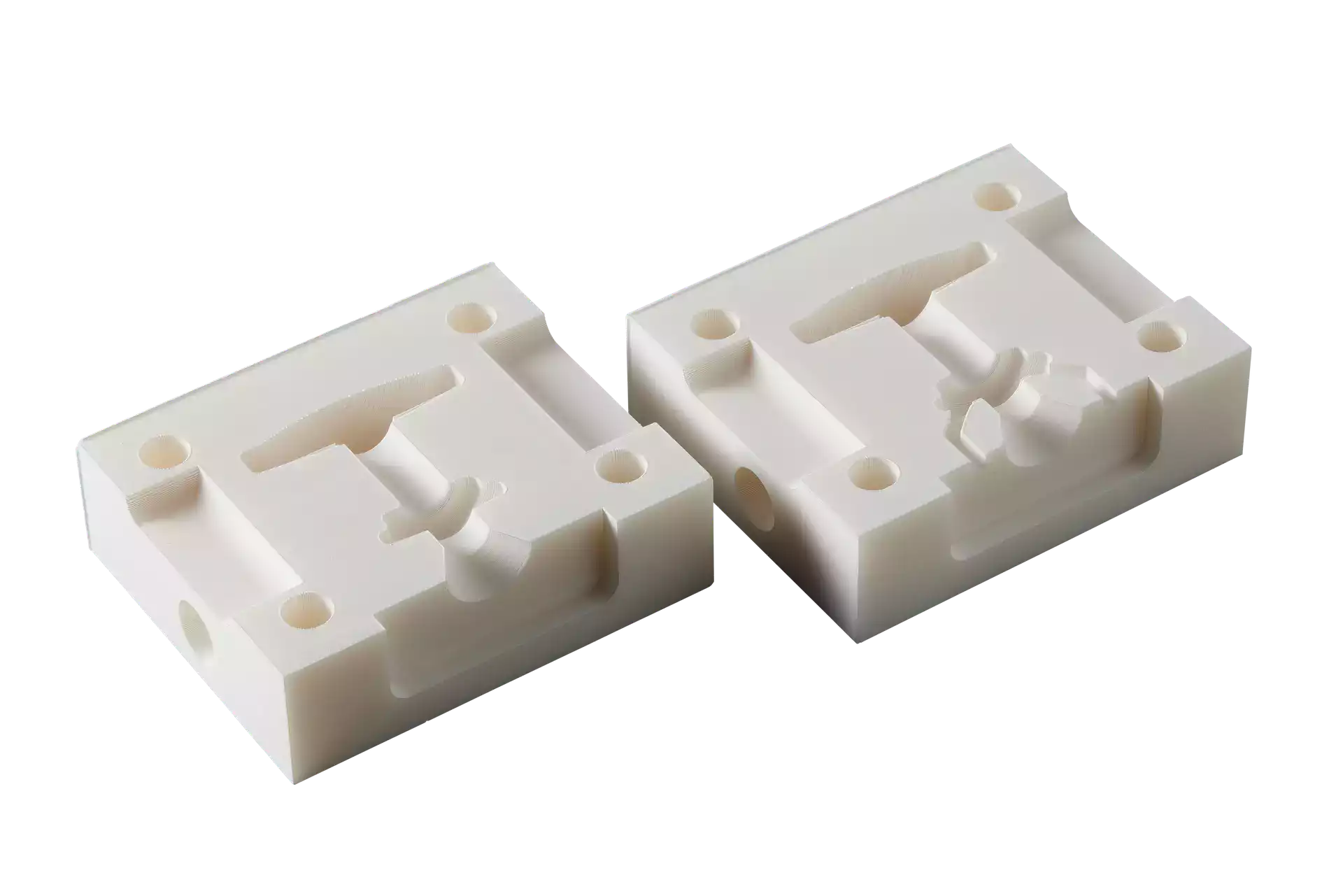

New Tough Resins Rival Injection-Molded Plastics

Print Tough, Impact-Resistant Parts

- HOME

- INDUSTRIES

- DIGITAL MANUFACTURING

- Formlabs

Introducing Form 4L & 4BL: High-Speed, Precision 3D Printing

Experience lightning-fast, high-precision 3D printing for large-scale projects and healthcare applications with Form 4L & 4BL

- HOME

- INDUSTRIES

- DIGITAL MANUFACTURING

- Formlabs

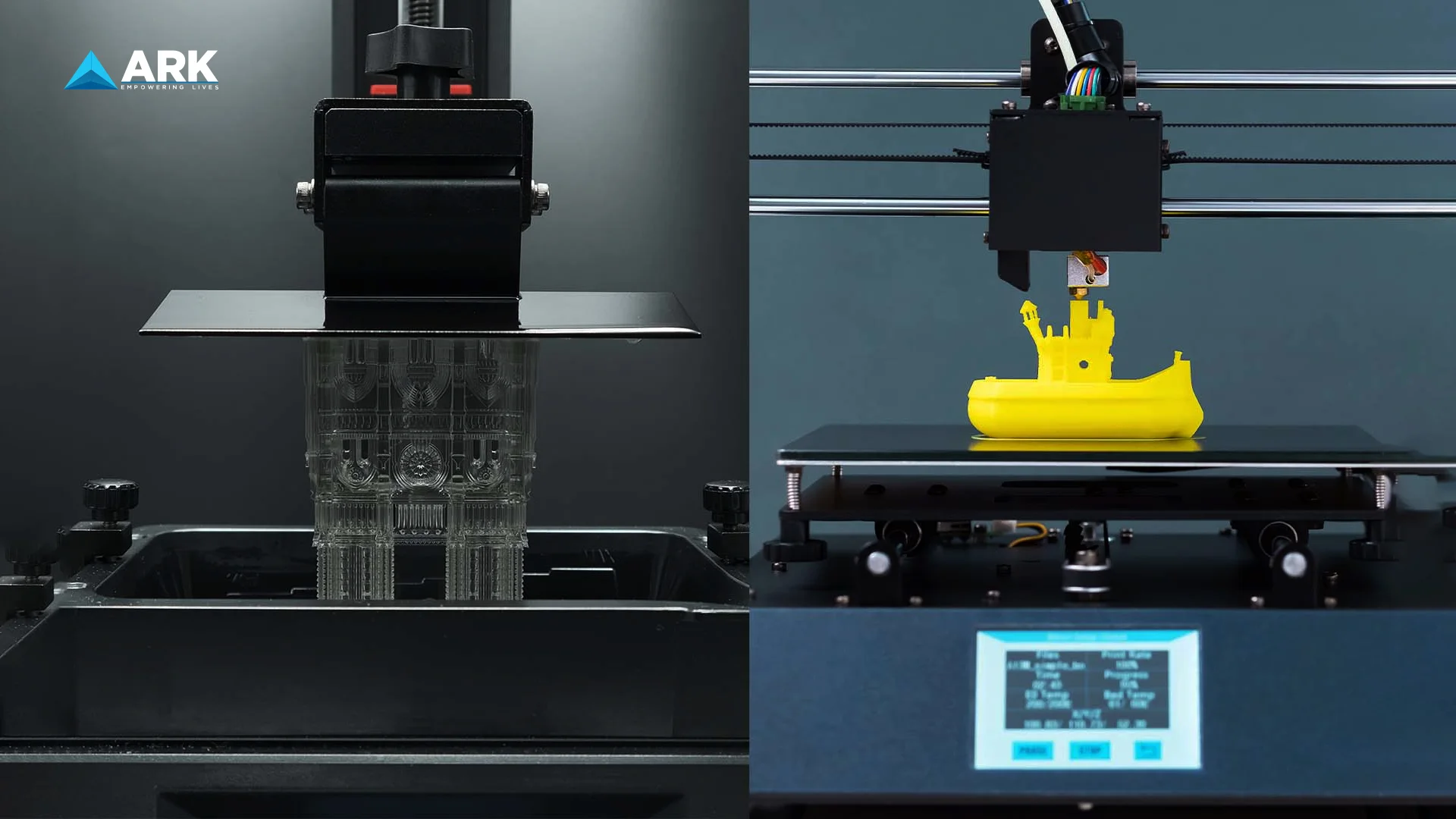

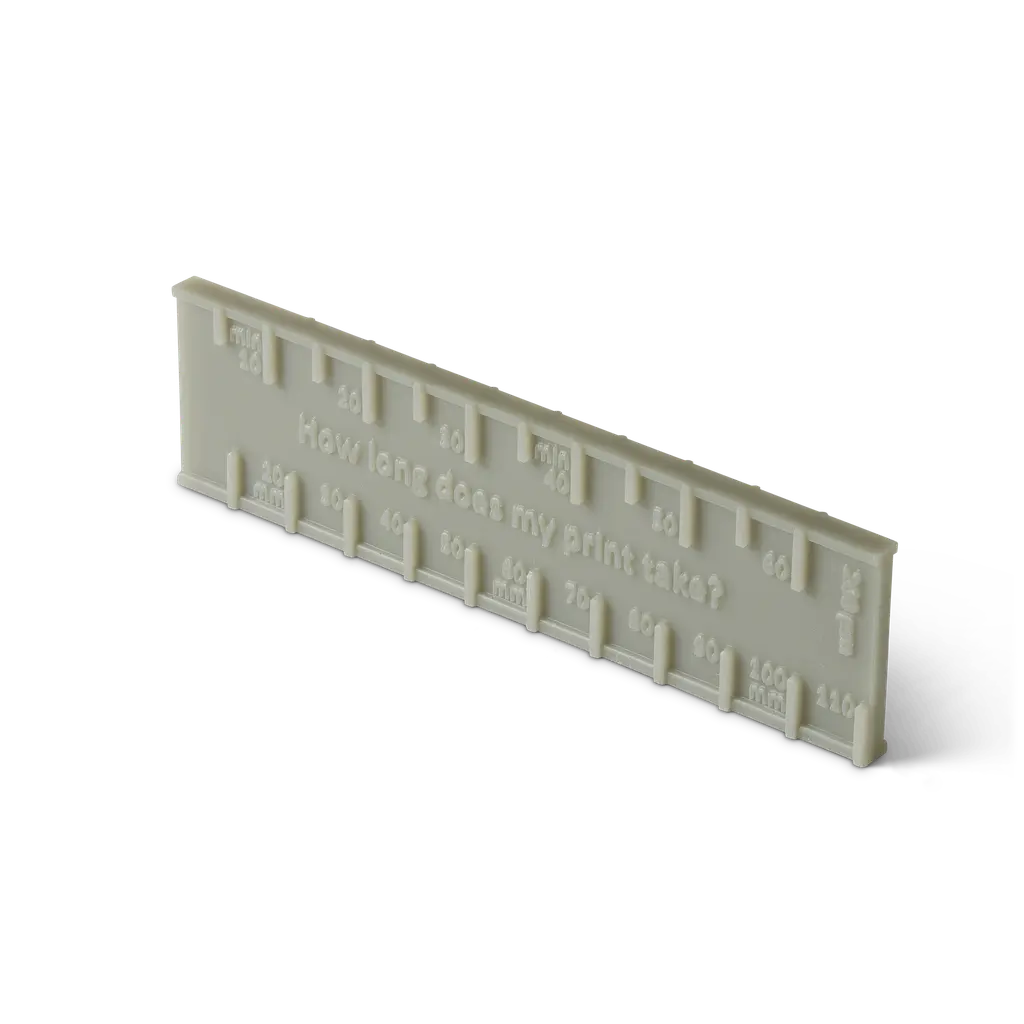

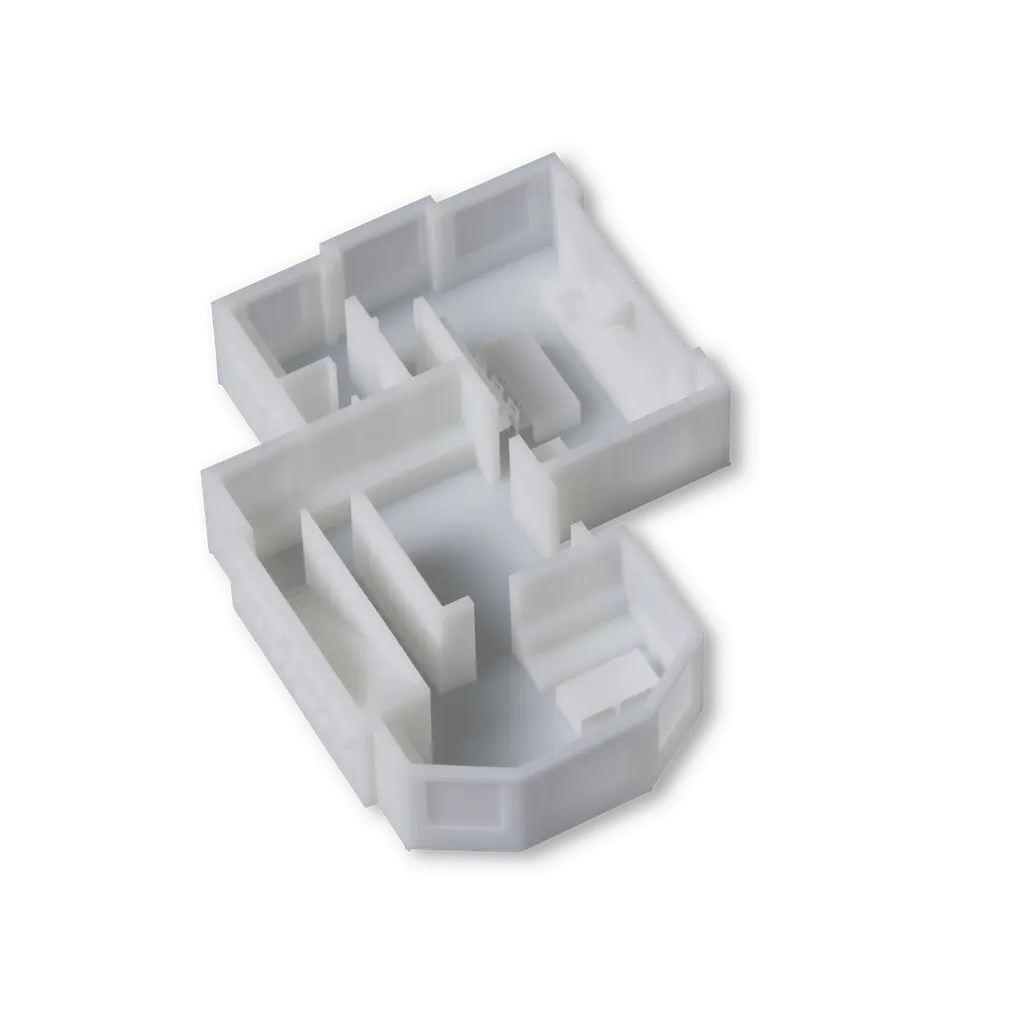

Make Anything with Formlabs 3D Printers

Unlock the full potential of your ideas with Formlabs 3D printers, offering rapid prototyping, tooling, end-use part production, manufacturing aids, and high-resolution models with unmatched precision and efficiency.

Founded in 2011 and headquartered in Somerville, Massachusetts, Formlabs is dedicated to democratizing digital fabrication. Our cutting-edge portfolio includes the Form 4, Form 4B, and Form 4L SLA printers, along with the Fuse Series SLS printers. With a strong global presence and a focus on innovation, we empower industries to create everything from high-precision parts to fully customized products. Our comprehensive ecosystem of advanced hardware, post-processing solutions, and high-performance materials continues to set the benchmark for professional 3D printing and shape the future of digital fabrication.

Precise and Versatile 3D Printing for

Professionals Across Industries

Formlabs 3D printers are engineered to enhance your industry with advanced stereolithography (SLA) and selective laser sintering (SLS) technology, offering high performance at a fraction of the cost of traditional industrial 3D printers or service bureaus.

Whether you’re in engineering, manufacturing, automotive, aerospace, dental, medical, education, entertainment, jewelry, or audio, Formlabs provides precise and versatile solutions tailored to meet the needs of your sector. Elevate your business with innovative 3D printing that delivers exceptional results and cost-efficiency.

Formlabs Professional 3D Printers: Blazing Speed and Precision to

Turn Bold Ideas into Full-Scale Reality

Formlabs Materials Library

Formlabs offers a versatile material library, enabling you to create products ranging from biocompatible medical devices to durable prototypes. Their materials span categories like General Purpose, Engineering, Dental, Medical, and Jewelry. Explore materials by type (SLA or SLS), applications, compatibility, and characteristics. Find options suited to your specific project needs, including biocompatible and high-precision choices.

FAQ's

ARK Infosolutions is the authorized value-added distributor and reseller for Formlabs in India. ARK supports customers with Formlabs 3D printer selection, deployment guidance, materials access, training coordination, and post-sales technical support across India.

Formlabs is a professional 3D printing company specializing in SLA (stereolithography) and SLS (selective laser sintering) technologies. Formlabs printers are used for prototyping, functional testing, and end-use part production across engineering, manufacturing, healthcare, education, and design workflows.

SLA 3D printing uses a laser to cure liquid resin layer by layer, producing highly detailed parts with smooth surface finishes. SLS 3D printing uses a laser to fuse powdered materials, creating strong and functional parts without support structures. Formlabs offers both technologies to address different prototyping and production needs.

Formlabs SLA printers use photopolymer resins, including standard, engineering, flexible, elastic, and biocompatible materials. Formlabs SLS printers primarily use nylon-based powders such as PA12 and glass-filled nylon, suitable for durable functional parts and low-volume production.

Yes. Formlabs 3D printers are used for rapid prototyping, small-batch manufacturing, and end-use part production. Compact systems support iterative design and testing, while larger-format models enable production of bigger components and higher volumes.

ARK Infosolutions supports Formlabs customers in India with pre-sales consultation, product demonstrations, installation assistance, materials guidance, workflow support, and coordination of training and technical assistance. This helps organizations adopt Formlabs 3D printing effectively within digital manufacturing environments.

To enquire about Formlabs 3D printers in India, you can contact ARK Infosolutions by submitting an enquiry through the website or emailing formlabs@arkinfo.in. The team assists with printer selection, materials, pricing, deployment guidance, and training support.

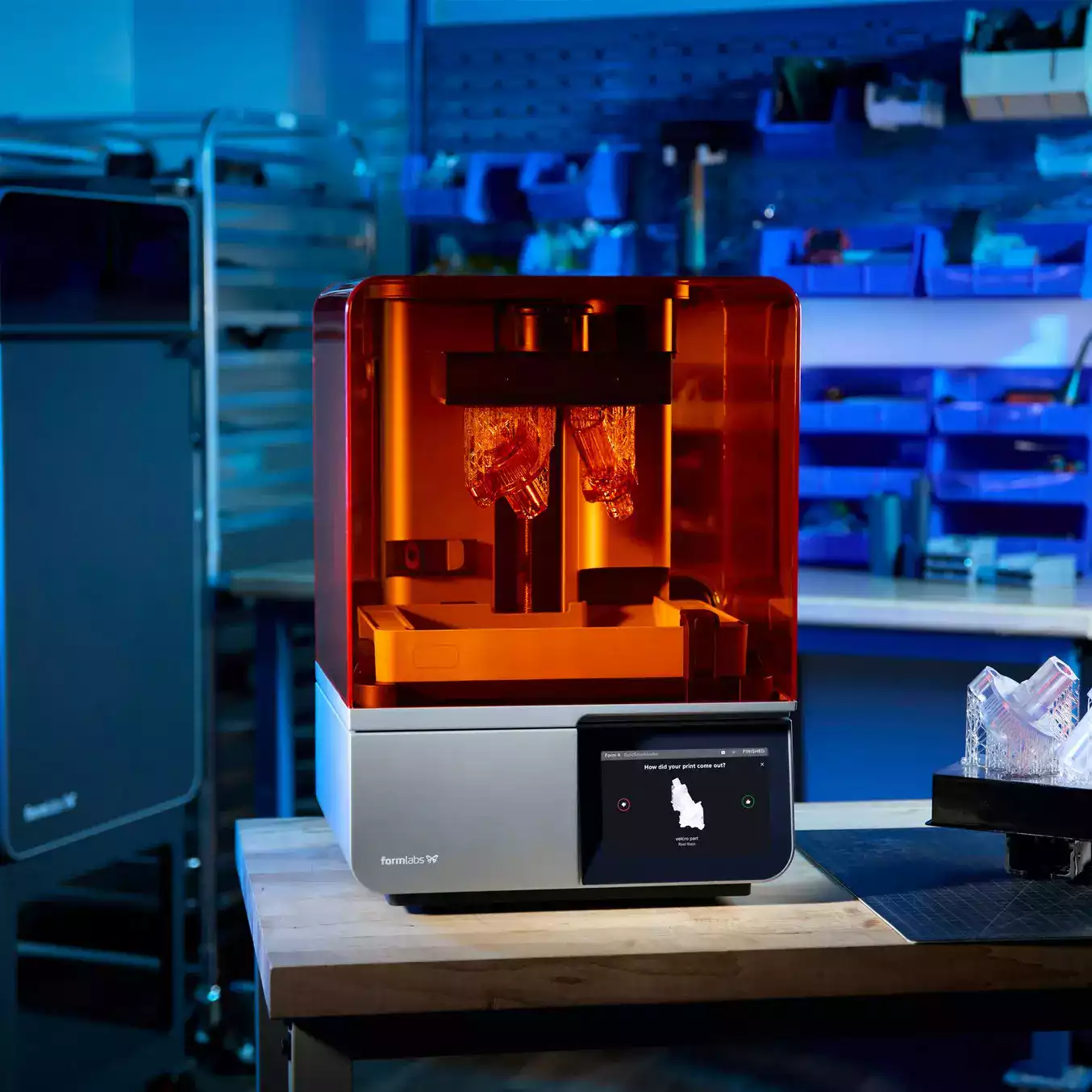

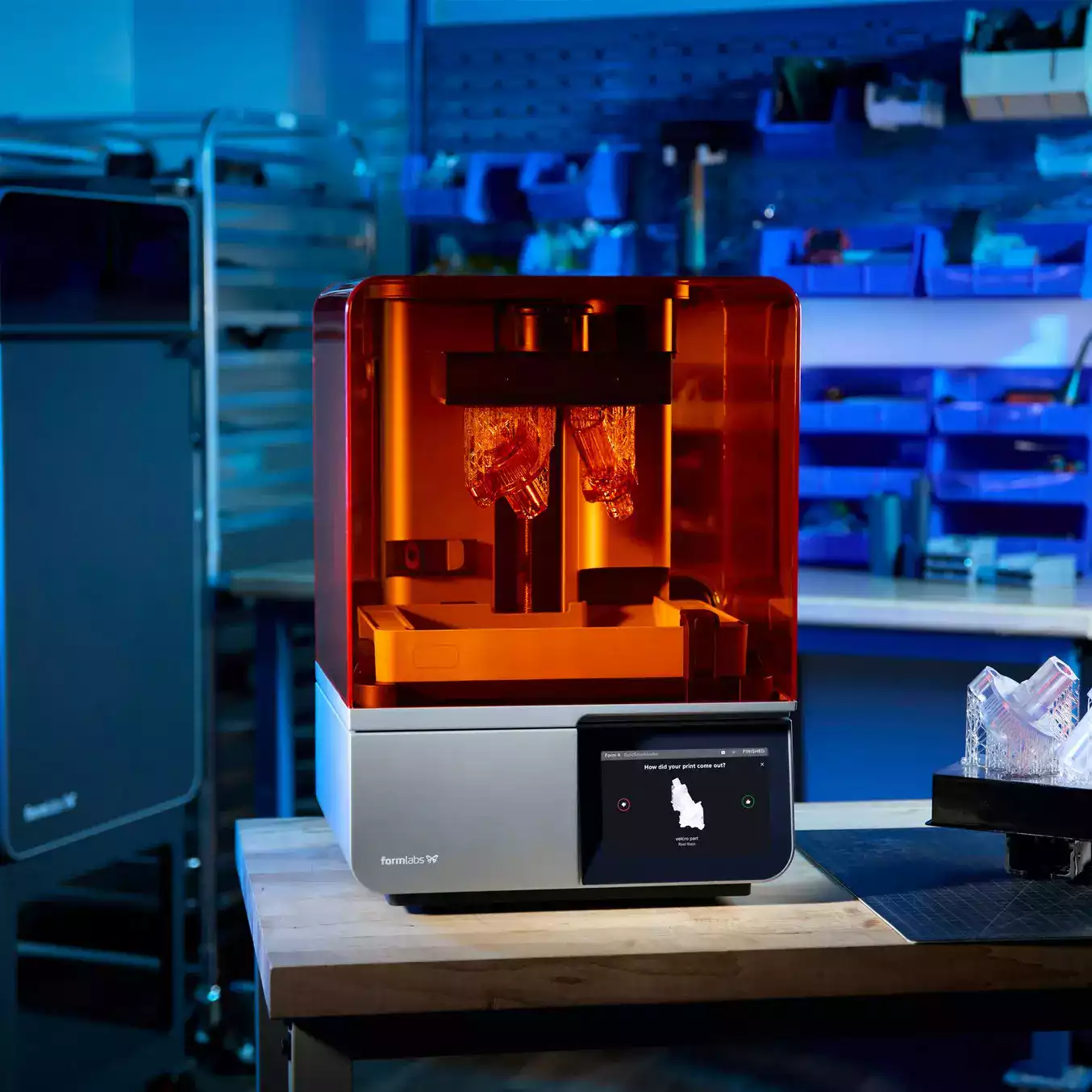

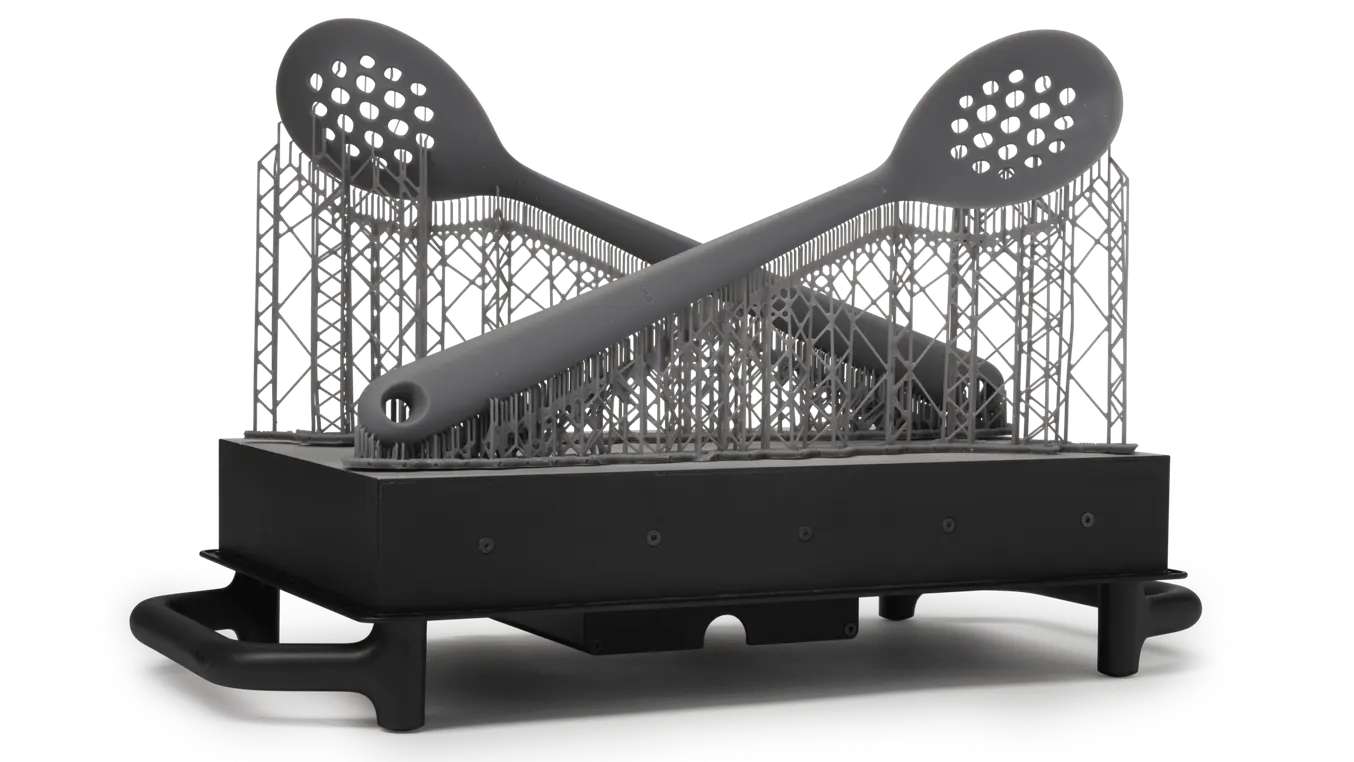

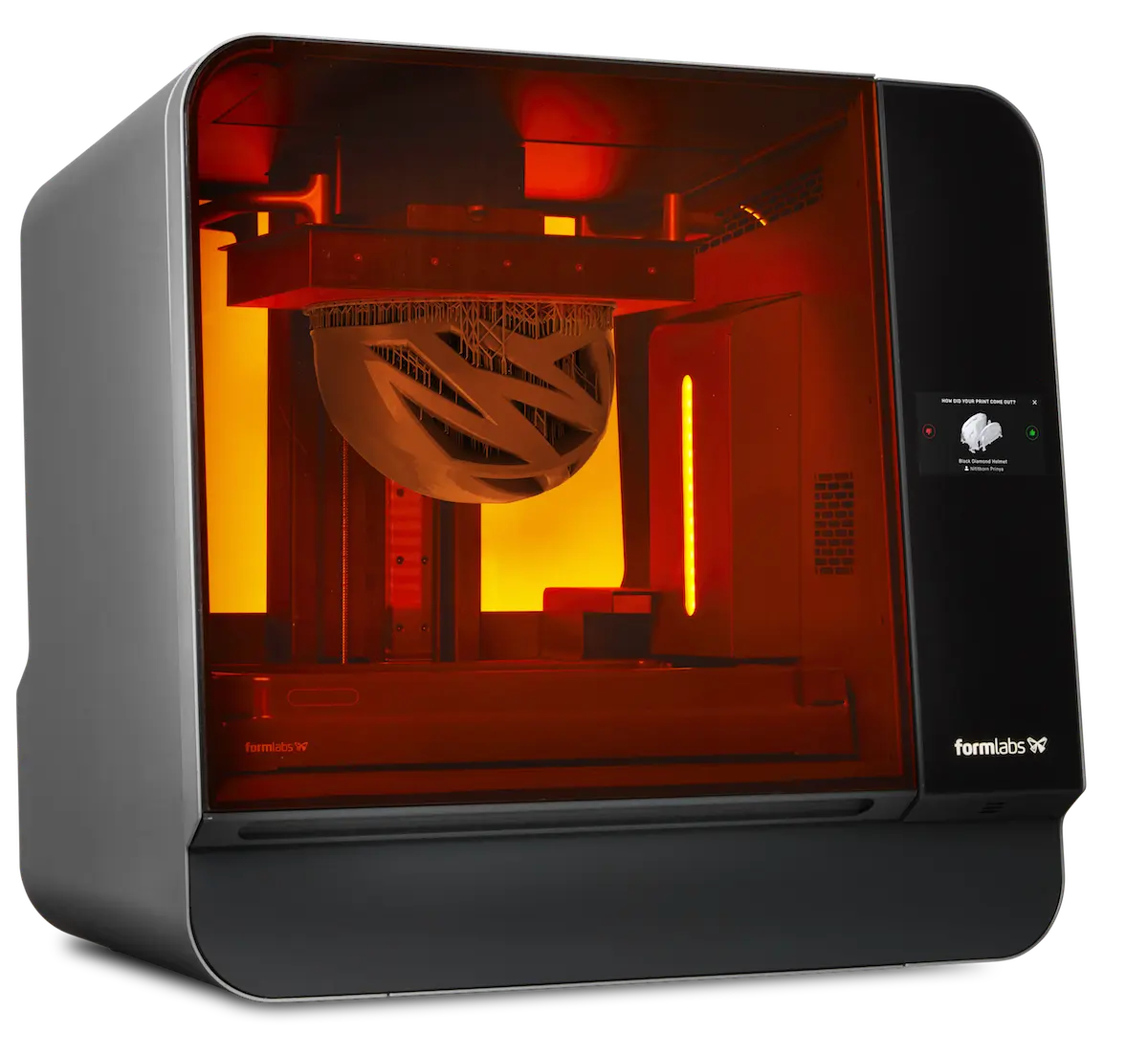

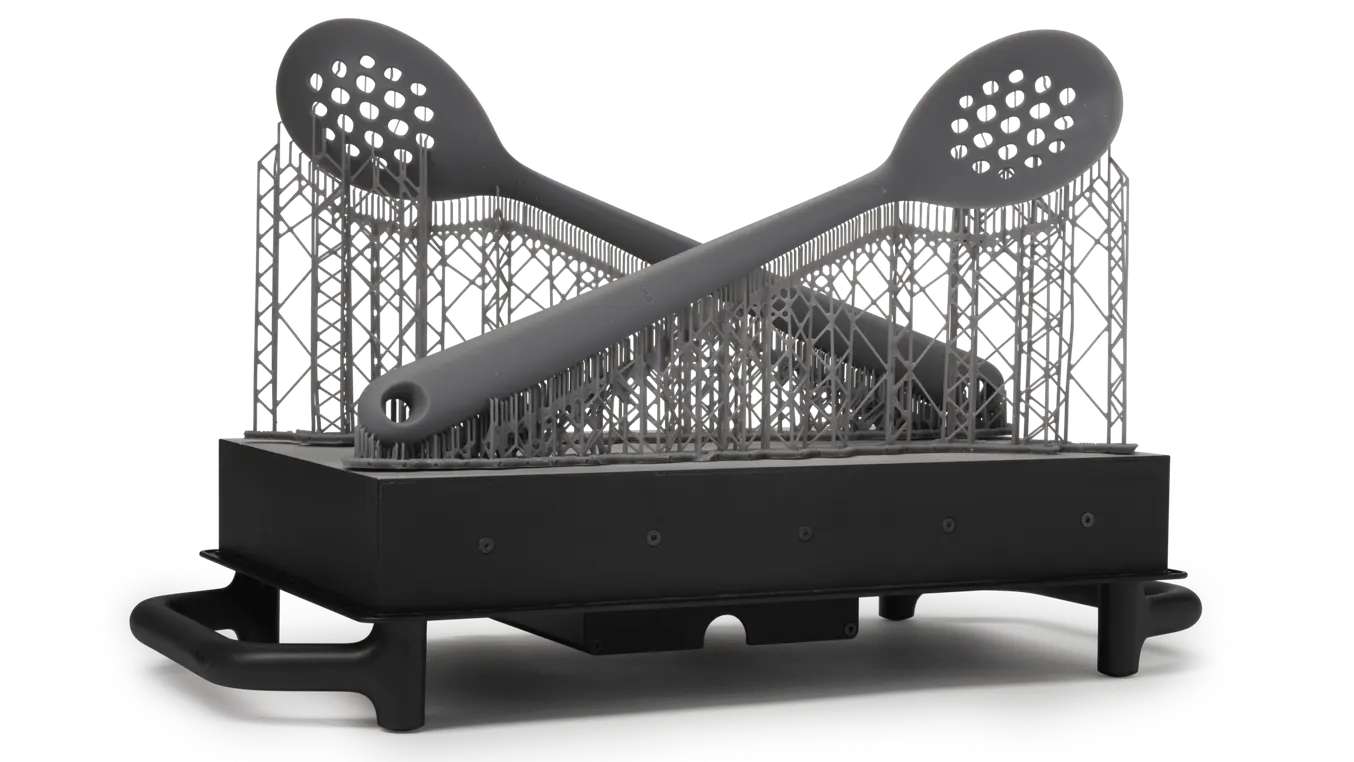

Form 4L

Where speed meets Precision

The Form 4L's incredible speed is powered by Formlabs’ state-of-the-art Low Force Display™ Print Engine, an ingenious combination of ultra-high-power LEDs, precision collimating lenses, optical filters, and a durable liquid crystal display.

This advanced system ensures rapid resin curing for every layer, regardless of the part's size or quantity. With ultra-tight tolerances, every part printed on the Form 4L-no matter the resin-will consistently align with your exact design specifications, every single time.

Build Volume

35.3 × 19.6 × 35.0 cm

13.9 x 7.7 x 13.8 in

Technology

Low Force Display™ (LFD)

- Blazing Fast: Large prints in under 6 hours.

- Large Build Area: 4.6X Larger build volume than form 4.

- User-Friendly: Automatic resin dispensing and easy-to-use software.

- Reliable: Large format 3D printing that you can depend on.

- Low Downtime: Replaceable parts for minimal downtime.

- Big Parts: Solve big problems with big parts.

- Full-size rapid prototyping.

- Large-scale models.

- Rapid tooling and manufacturing aids.

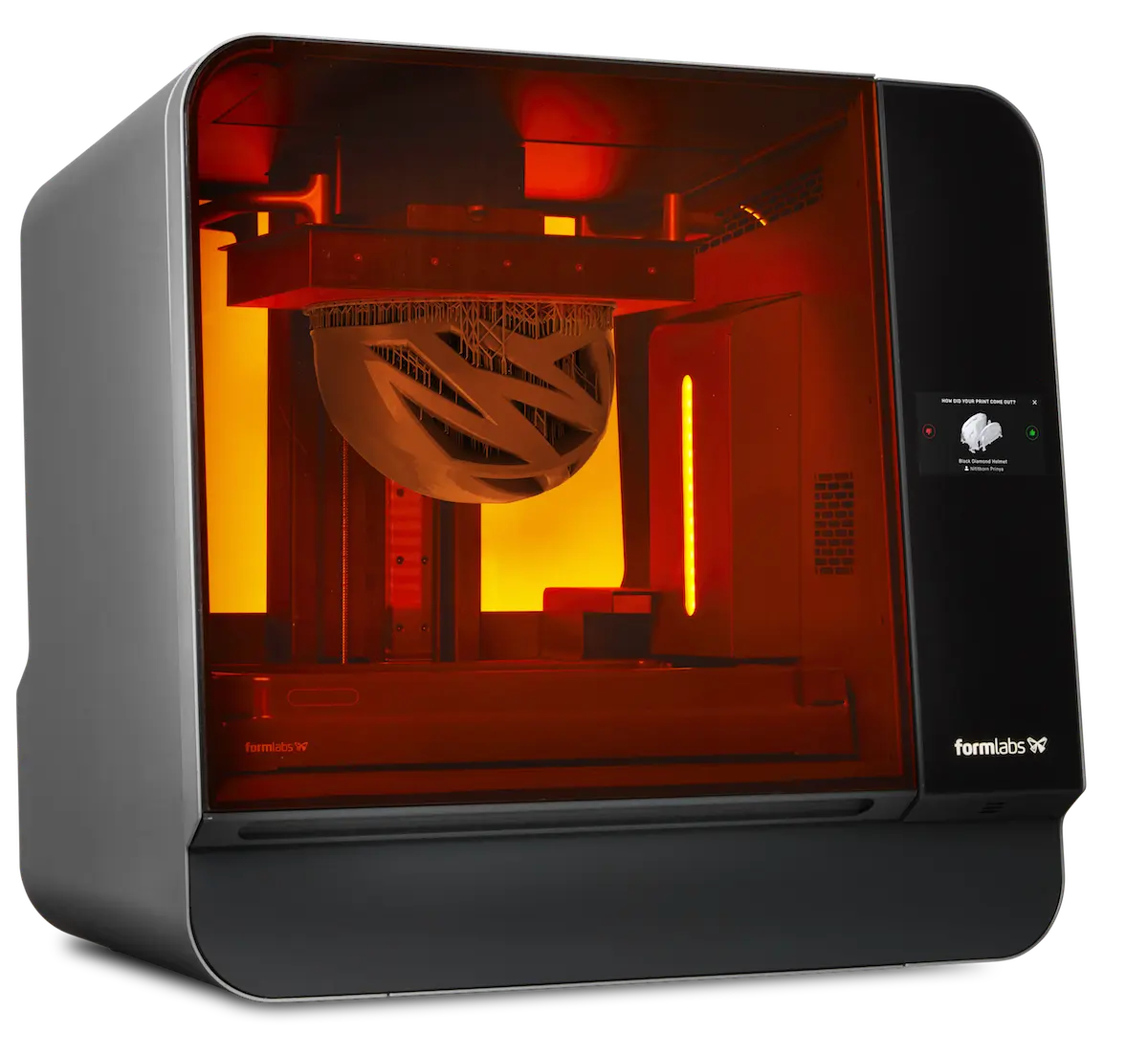

Form 4BL

Blazing Fast with accurate print engine

The Form 4BL's lightning-fast performance is powered by Formlabs’ cutting-edge Low Force Display™ Print Engine, a sophisticated blend of ultra-high-power LEDs, precision collimating lenses, optical filters, and a durable liquid crystal display.

This advanced technology rapidly cures each resin layer, regardless of part size or volume, ensuring flawless surface accuracy. From models to appliances and prosthetics, you can expect a perfect fit every time.

Build Volume

35.3 × 19.6 × 35.0 cm

13.9 x 7.7 x 13.8 in

Technology

Low Force Display™ (LFD)

- Versatile: Industry-leading materials and Open Platform.

- Stunning parts: Stunning parts that always fit.

- Intuitive: Anyone can learn in 15 minutes.

- Reliable: Large format 3D printing that you can depend on.

- Large parts needing biocompatibility and sterilization.

- Full-size anatomical models, including pediatric and adult.

- Medical device prototypes, jigs, fixtures, and end-use parts.

- Surgeon-specific or patient-specific surgical tools.

- Surgical planning models for FDA-cleared diagnostics.

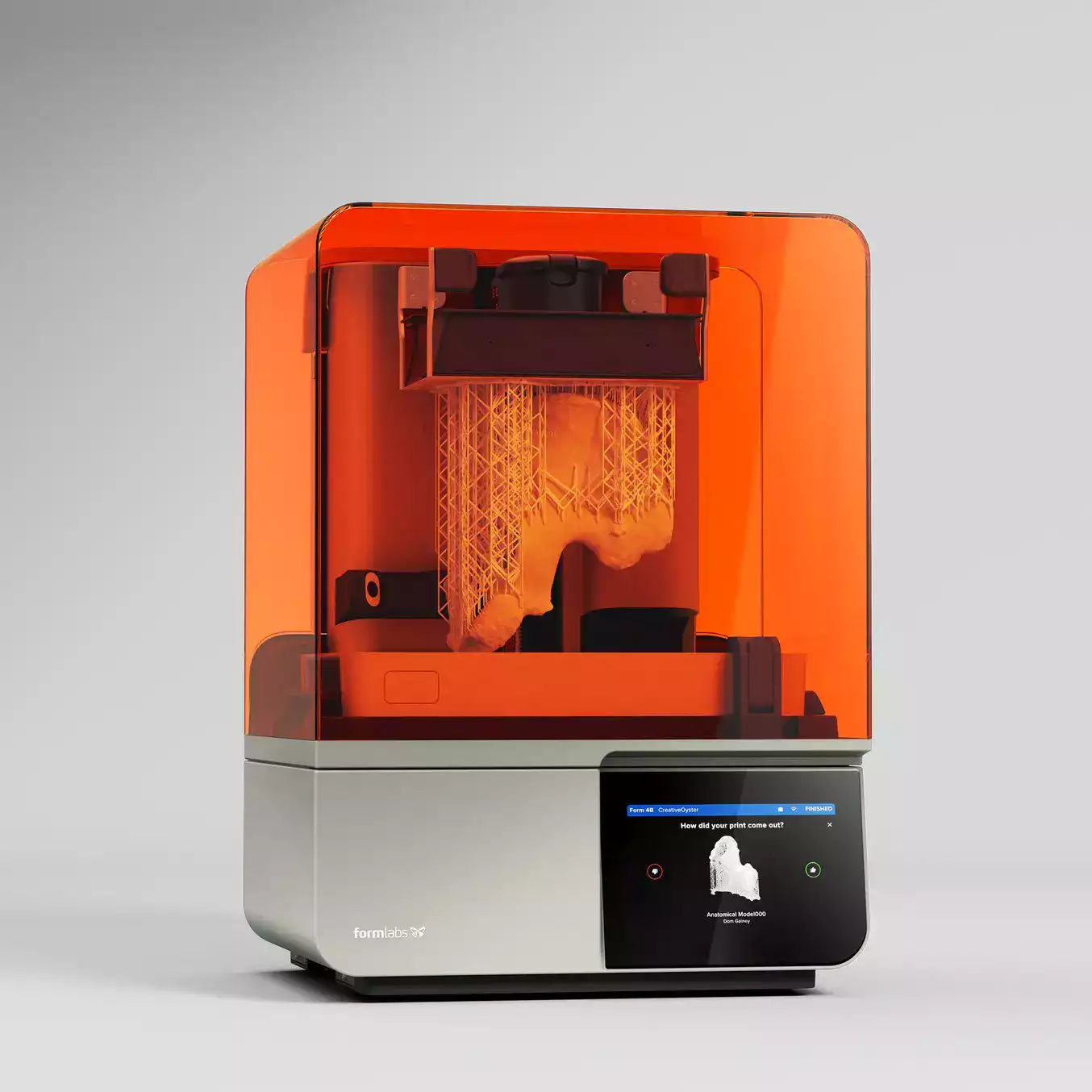

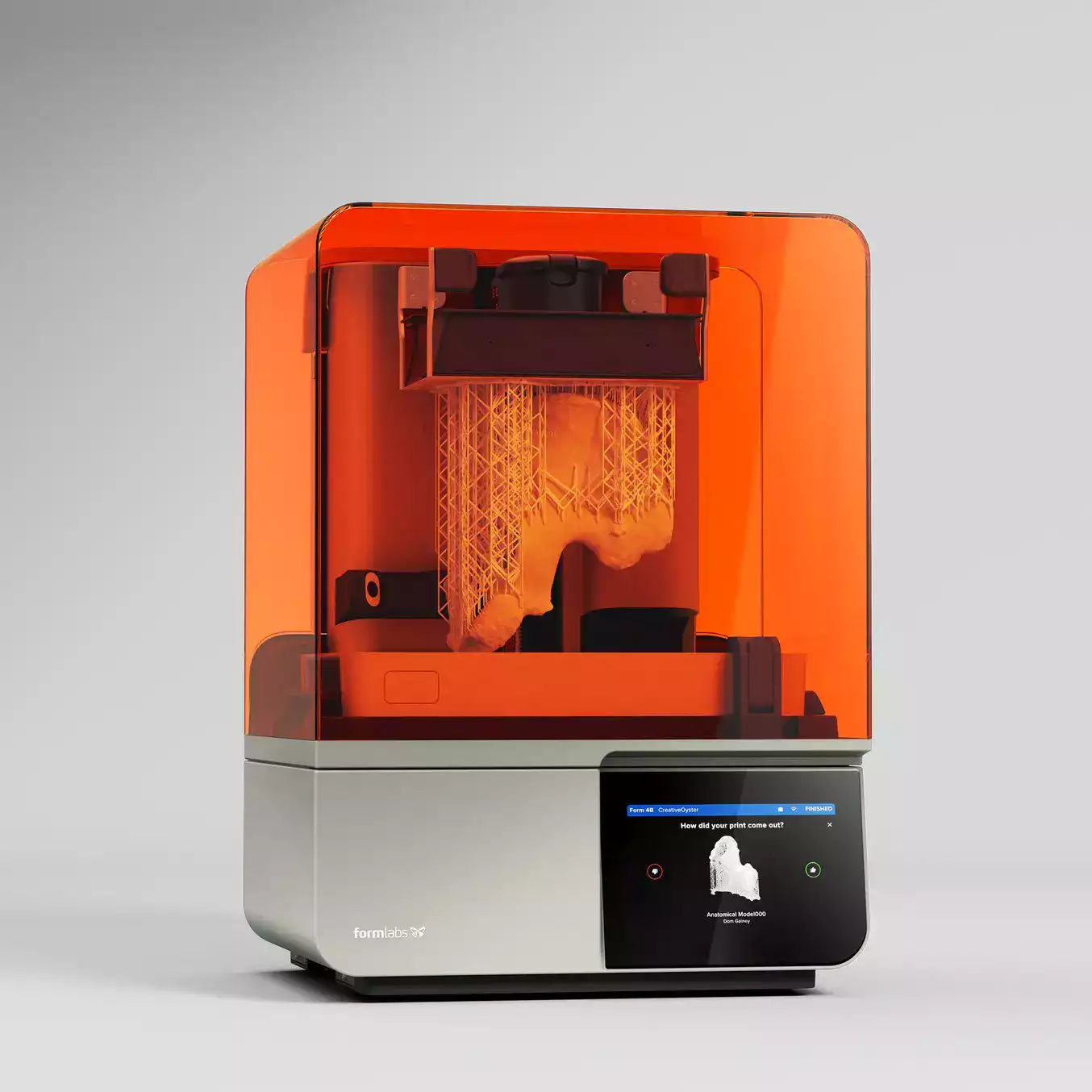

Form 4

Blazing Speed Meets Industrial Production

Bring your ideas to life faster than ever with the Form 4 professional 3D printer ecosystem, offering streamlined workflows, exceptional reliability, and outstanding part quality.

The Form 4 is a blazing-fast masked SLA 3D printer, combining an industry-leading materials library with a highly accurate and dependable print engine. With tight tolerances, every resin-printed part on the Form 4 consistently matches your design specifications.

Build Volume

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Technology

Masked Stereolithography (MSLA)

- Blazing Fast: Complete most prints in under 2 hours

- Versatile: Wide range of resins for any application

- Intuitive: Learn to use in just 15 minutes

- Reliable: Industry-leading print success rate

- Accurate: Precision that rivals injection-molded parts

- Rapid prototyping and production.

- Rapid tooling and manufacturing aids.

- Patterns for molds and casting.

- High-precision model making.

Form 4B

Blazing Speed Meets Surgical Precision

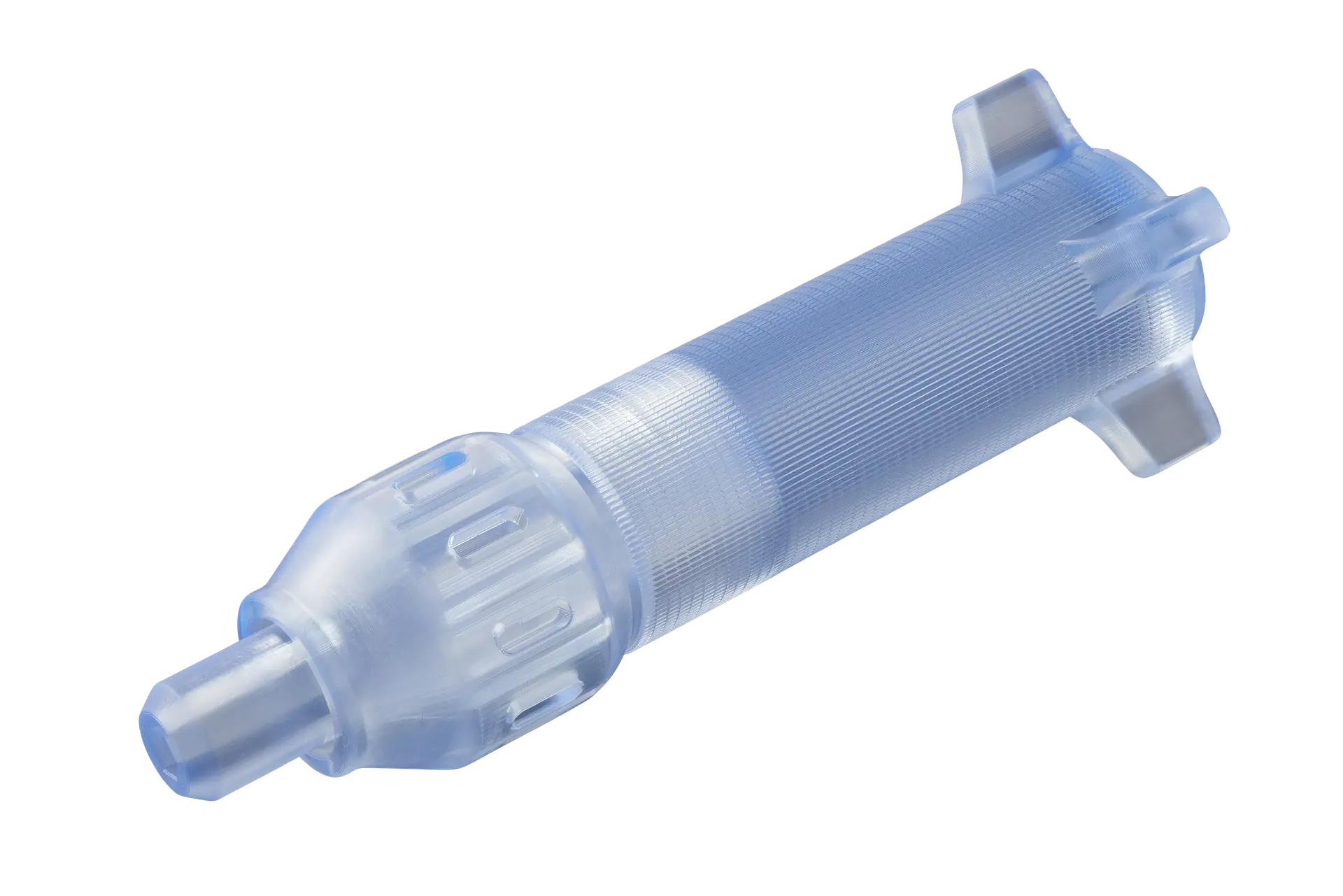

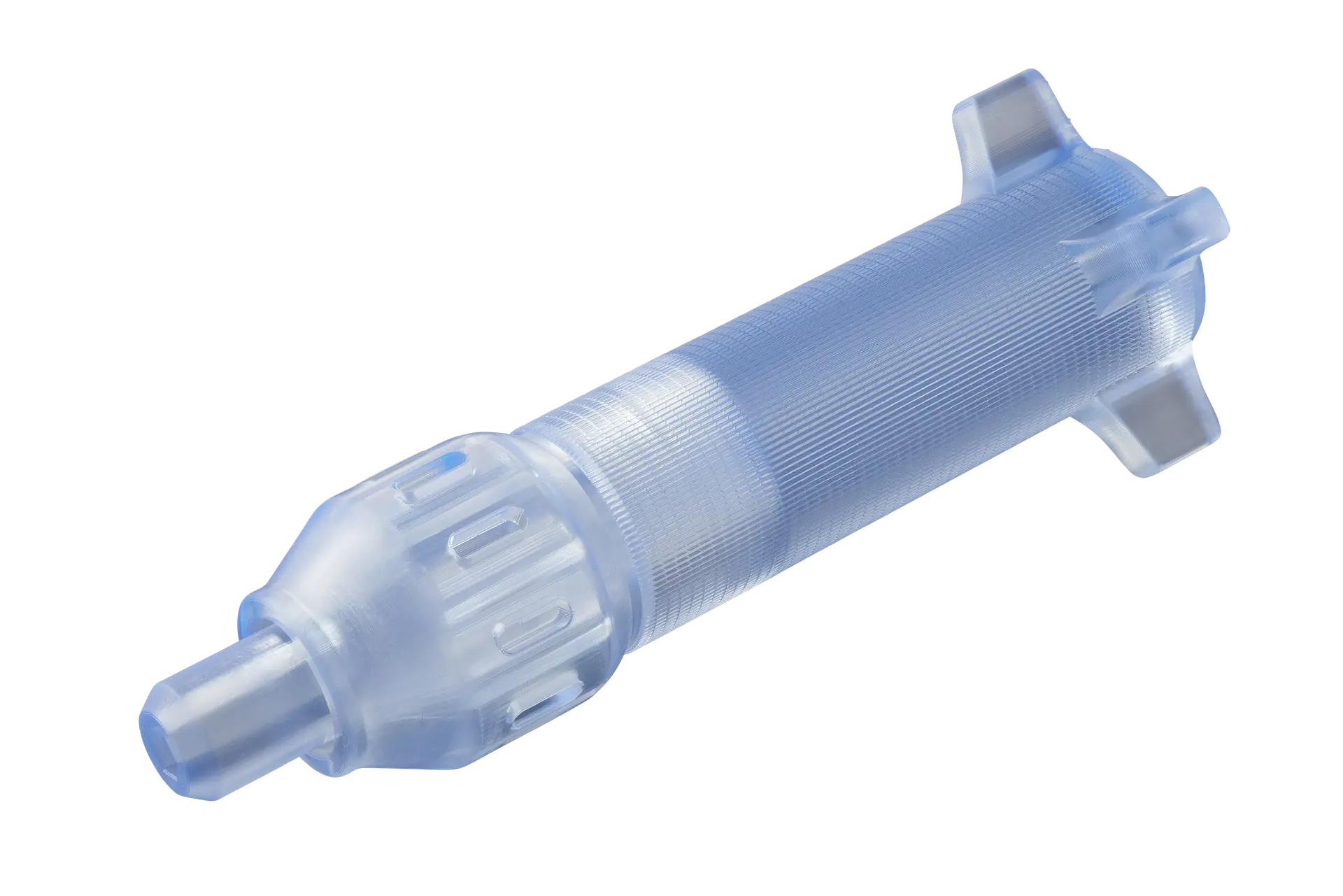

Quickly create biocompatible, sterilizable anatomical models and medical devices with the Form 4B, a blazing-fast medical 3D printer designed for healthcare. Offering easy workflows, exceptional reliability, versatile materials, and stunning part quality, the Form 4B provides access to the most diverse materials library in the industry.

Build Volume

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Technology

Masked Stereolithography (MSLA)

- Fast: 4x faster with 30% more build volume

- Precise: Delivers accurate prints, every time

- Reliable: Industry-leading print success rate

- Small to medium parts requiring biocompatibility and sterilization.

- Medical device prototypes, jigs, fixtures, molds, and end-use parts.

- Patient-specific anatomical models and surgical instruments.

- Visual aids for diagnosis and education.

- Surgical planning models for FDA-cleared diagnostic workflows.

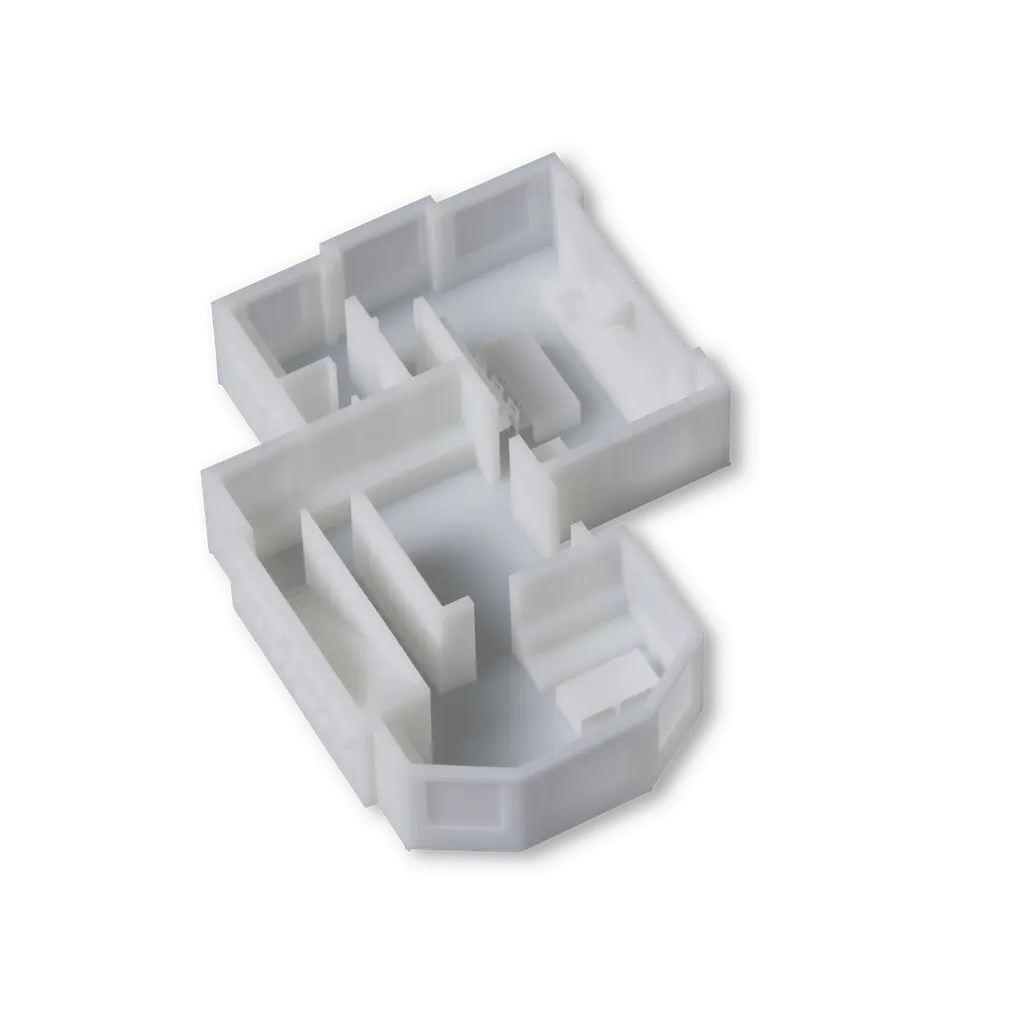

Form 3L

A Large Format 3D Printer That Reliably Brings

Full-Scale Ideas To Life

Take charge of large-format production and realize your biggest ideas with the Form 3L. This cost-effective 3D printer delivers exceptional detail without compromising on quality.

Build Volume

33.5 × 20 × 32 cm

13.2 × 7.9 × 12.6 in

Technology

Stereolithography (SLA)

- User-Friendly: Automatic resin dispensing and easy-to-use software.

- High Precision: 25-micron resolution for smooth, detailed prints.

- Automated Setup: Preform software optimizes print settings.

- 24/7 Performance: Sensors and cloud monitoring for nonstop printing.

- In-Field Repairs: Replaceable parts for minimal downtime.

- Full-size rapid prototyping.

- Large-scale models.

- Rapid tooling and manufacturing aids.

Form 3BL

A Large Format 3D Printer Developed for Healthcare

3D print full-size, patient-specific adult anatomy or large medical devices with the Form 3BL. This large-format medical 3D printer is compatible with a wide range of SLA materials, including biocompatible and sterilizable resins, all produced in our ISO 13485 certified, FDA-registered facility.

Build Volume

33.5 × 20 × 32 cm

13.2 × 7.9 × 12.6 in

Technology

Stereolithography (SLA)

- Easy Integration: Automatic resin dispensing and user-friendly software.

- 24/7 Operation: Minimal supervision with remote printing.

- High Quality: Micron-level detail and smooth finishes.

- Versatile Materials: Supports the full SLA materials library.

- Precision: 25μm resolution and 250mW laser power.

- Large parts needing biocompatibility and sterilization.

- Full-size anatomical models, including pediatric and adult.

- Medical device prototypes, jigs, fixtures, and end-use parts.

- Surgeon-specific or patient-specific surgical tools.

- Surgical planning models for FDA-cleared diagnostics.

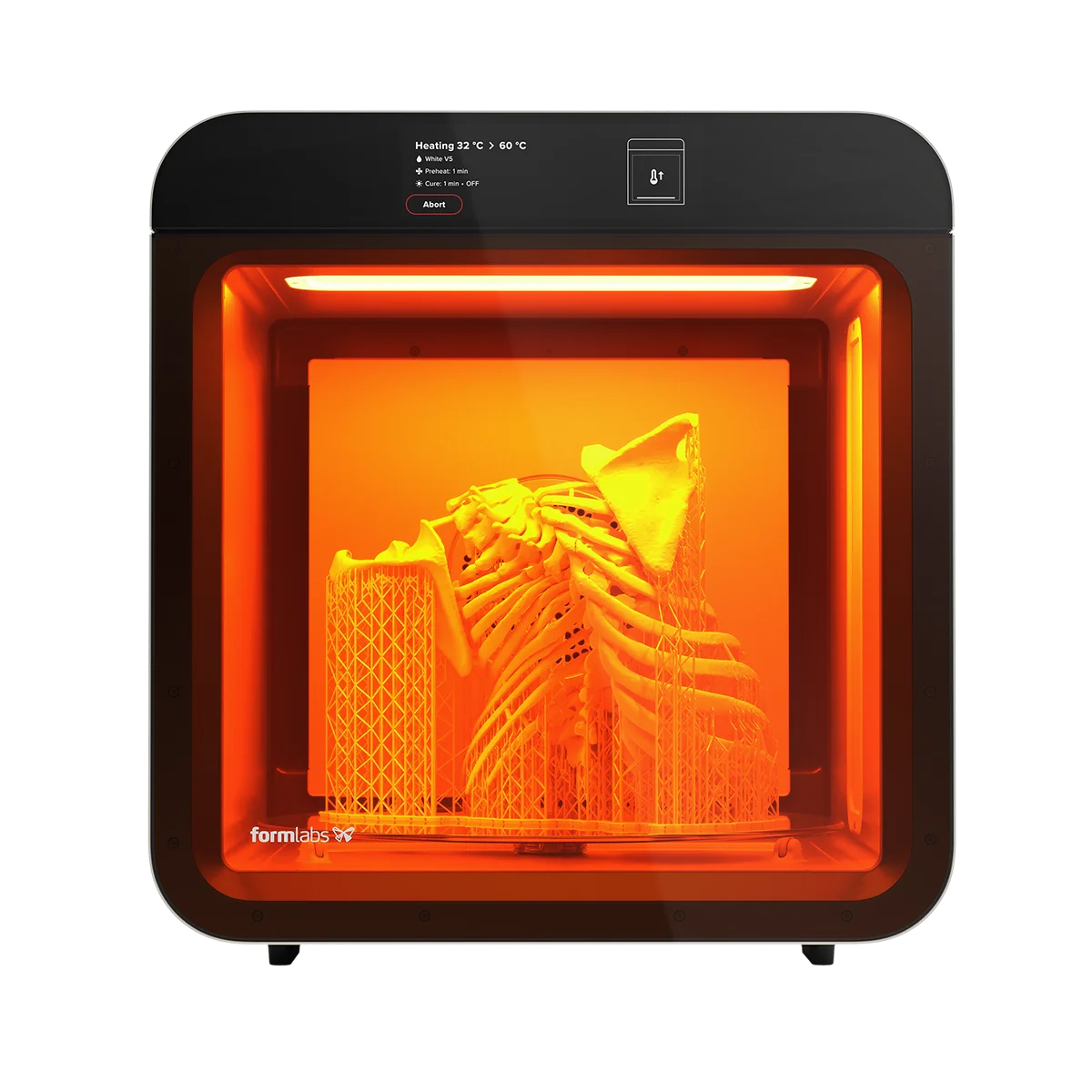

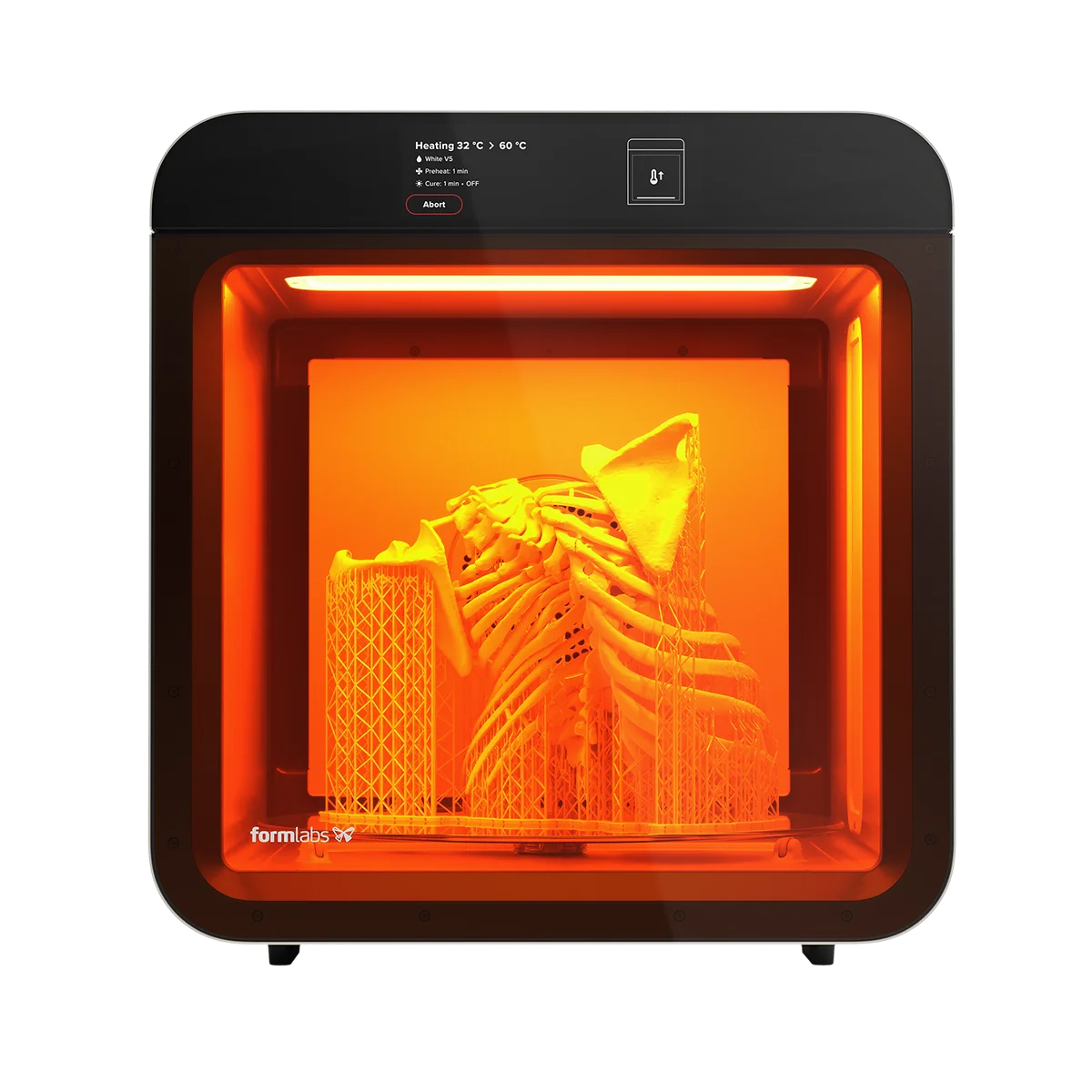

Form Cure L V2

Fastest, Most Consistent Large – Format Cure unit ever built by Formlabs

Form Cure L V2 precisely combines heat and 405 nm light to deliver tough, strong prints with unprecedented speed and consistency. Now you can post-cure large Form 4L/BL prints in as little as 60 seconds, with 5x more UV power, faster heat-up times, and a 26% reduction in overall footprint from the previous generation while curing up to 19% larger parts. To begin curing, just select a validated preset for Formlabs 45+ materials. Advanced users can customize time and temperature to fit their specific needs.

Post-curing completes the chemical reaction started during printing, enhancing final part strength, toughness, heat resistance, and creep resistance while creating a harder, less tacky surface.

For biocompatible materials, post-curing is necessary to achieve the safety standards determined by regulatory agencies.

The new Form Cure L V2 is the fastest, most consistent large-format cure unit ever built by Formlabs — designed to perfectly complement the Form 4 and 4L printers. It delivers production-ready parts in minutes with precision and reliability you can trust.

- Faster, Smarter Post-Processing: Cures large batches of parts in minutes instead of hours, freeing up operators and printers for more production runs per day. Customers reclaim hours of idle time and accelerate delivery, improving their cost per part and time-to-market.

- Predictable Quality: Uniform, validated curing eliminates reprints and wasted materials. Every part meets production specs the first time, reducing scrap costs and workflow interruptions.

- Simplified Operation: Preset cycles and intuitive controls make curing foolproof, even for new operators, cutting training time and preventing costly mistakes.

Form Wash (2nd Generation)

Effortless Cleaning and Drying with Form Wash

Form Wash automates the cleaning of printed parts with IPA or alternative solvents, ensuring thorough and efficient results. Parts can be left on the Build Platform or placed in the wash basket. The impeller provides precise agitation, reaching every detail for a complete clean. After the wash cycle, Form Wash automatically raises the parts out of the solvent for effortless air drying, streamlining your post-processing workflow.

- Adaptable to Build Platforms: Adjustable mounts accommodate various platform sizes and configurations.

- Enhanced Agitation: Delivers 3x more cleaning power for thorough part washing.

- Flexible Solvent Capacity: Supports solvent volumes between 7-15 liters to optimize efficiency for different part sizes.

- Solvent Compatibility: Designed for use with IPA, while also supporting alternative solvents like TPM.

- Automated Cleaning: Set the wash time (default 10 minutes) and clean up to 120 prints per solvent refill for streamlined workflow.

- Printer Compatibility: Form 4, Form 4B, Form 3/+, Form 3B/+, Form 2

- Dimensions: 31.5 x 29.3 x 40.5 cm (12.4 x 11.5 x 15.9 in)

- Height when open: 71.4 cm (28.1 in)

- Weight: 8.6 kg (18.9 lbs) without solvent

- Bucket Volume: 14.4 L (3.8 US gal)

- Maximum Part Size: 20 x 14.5 x 19.5 cm (7.9 x 5.7 x 7.6 in)

- Included Accessories: Wash Bucket, Wash Basket, Hydrometer, 2x Platform Mounts

- Power Requirements: 90–240 V, 2.0 A, 50/60 Hz, 50 W

- Compatible Solvents: Formlabs Resin Washing Solution, IPA, TPM, Water

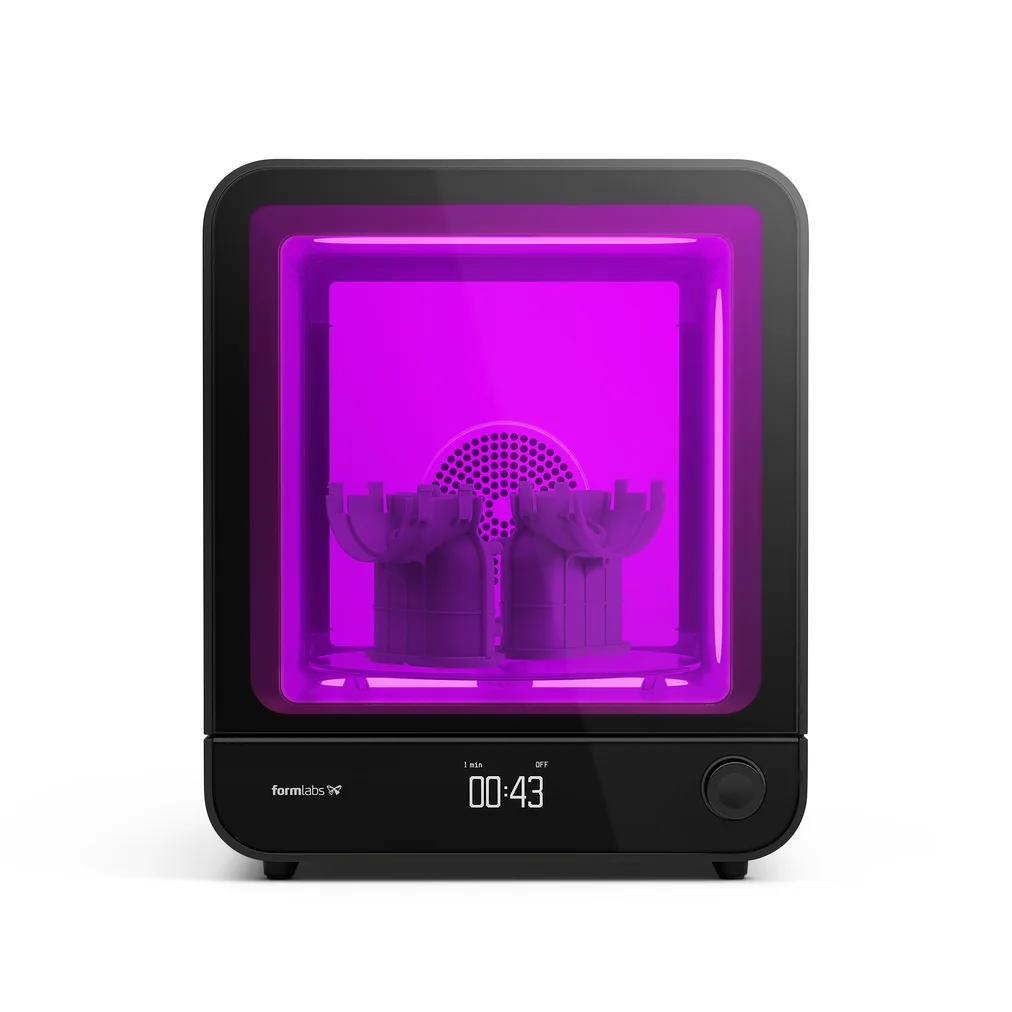

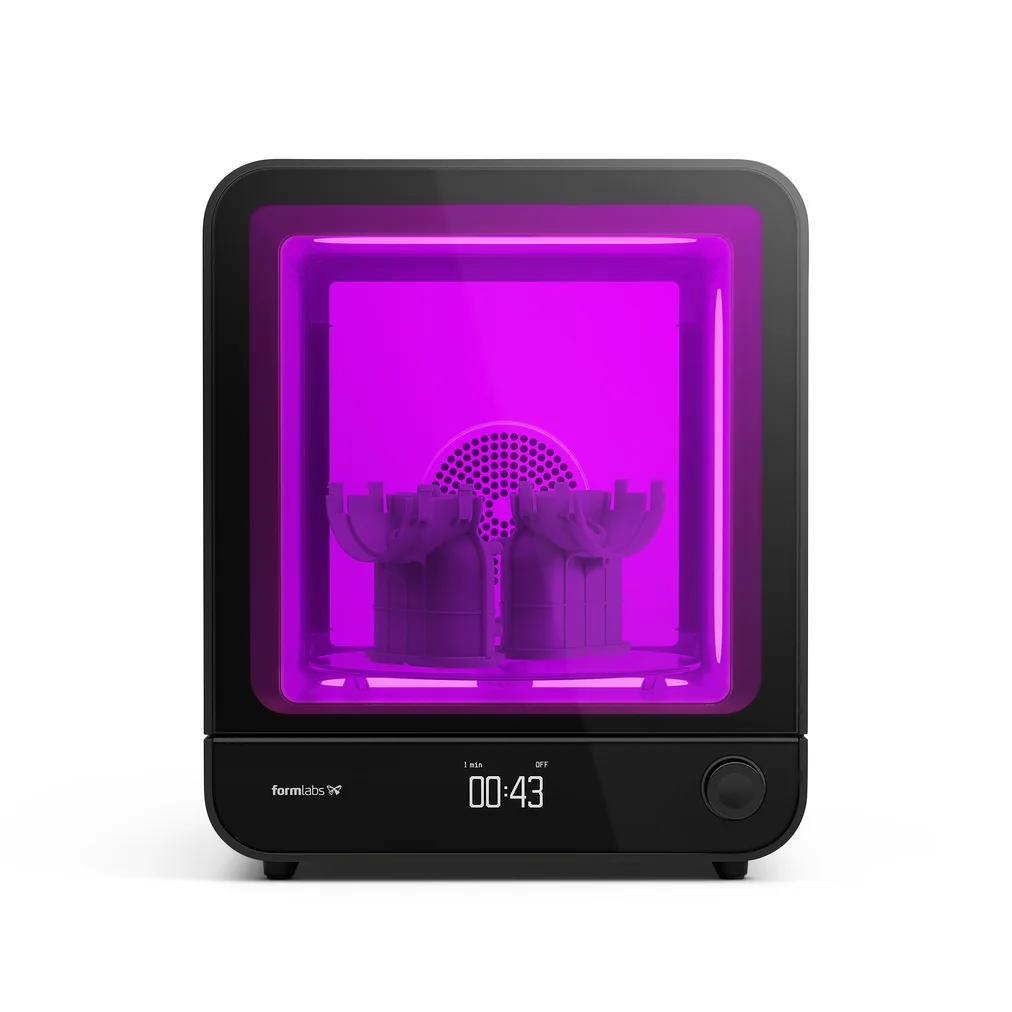

Form Cure 2nd Gen

Faster, Stronger, and More Precise Post-Curing

The Form Cure 2nd Gen delivers 3-5x faster curing with enhanced UV light and heat exposure, ensuring stronger and more reliable parts.

With 48 multi-directional LEDs (compared to 13 in the previous generation), an upgraded 150W LED power, and 50W LED radiant power, it provides 5x more 405 nm photon exposure, significantly accelerating final polymerization. This results in superior mechanical properties, making it ideal for high-performance and biocompatible applications.

- Nitrogen-Enabled Curing: Integrated nitrogen port enhances curing efficiency and material properties by minimizing oxygen inhibition.

- Ultra-Fast Heating: Reaches 60°C in ❮90 seconds, 80°C in ❮180 seconds, and 100°C in ❮270 seconds, ensuring rapid and consistent post-curing.

- Advanced Low-Warp Mode: Reduces warping for materials like Tough 1500, 2000, Rigid 4K/10K, and Durable, maintaining dimensional accuracy while balancing mechanical properties.

- High-Intensity, Even Curing: Equipped with 48 multi-directional LEDs, delivering 150W LED power and 5x more 405 nm photon exposure.

- Adaptive Curing Control: Supports both standard and low-warp curing modes, allowing users to tailor settings based on material.

- Printer Compatibility: Form 4, Form 4B, Form 3/+, Form 3B/+, Form 2

- Dimensions: 33.7 × 35.6 × 40.4 cm (13.3 × 14.0 × 15.9 in)

- Weight: 12.1 kg (26.7 lb)

- Turntable Diameter: 23.5 cm (9.25 in)

- Maximum Part Height: 205mm

- Operating Temperature: Suggested 18—28 °C (64—82 °F)

- Maximum post-cure temperature: 100 ºC (212 ºF)

- UV LED electrical power: 150 W

- UV LED radiant power: 50 W

- LED Wavelength: 405 nm

- Power Requirements:

- Input (NA): 100 - 120 VAC, 50-60Hz, 15A

- Input (EU): 220 - 240 VAC, 50-60Hz, 8A

Form Cure

Optimize Strength & Safety with Form Cure

Post-curing enhances the strength and performance of stereolithography prints by maximizing material properties. For biocompatible materials, it is essential to meet regulatory safety standards. Form Cure ensures consistent post-curing by precisely applying heat and 405 nm light, optimizing the quality and reliability of your prints.

- Advanced Heating: Preheats the chamber for efficient post-curing.

- Uniform Exposure: Rotating turntable ensures consistent curing.

- Maximize Material Properties: Optimizes performance with default settings tailored to each material.

- Rapid, High-Intensity Curing: Achieves temperatures up to 80°C with 13 LEDs for effective curing.

- Precise Control: 405 nm wavelength light and adjustable temperature enhance material strength.

- Printer Compatibility: Form 4, Form 4B, Form 3/+, Form 3B/+, Form 2

- Dimensions: 26.2 x 26.2 x 34.0 cm (10.3 x 10.3 x 13.4 in)

- Height when open: 64 cm (25.2 in)

- Weight: 5.6 kg (12.4 lbs)

- Turntable Diameter: 19.3 cm (7.6 in)

- Maximum Part Height: 18.5 cm (7.28 in)

- Operating Temperature: Suggested 18—28 °C (64—82 °F)

- Maximum Cure Chamber Temperature: 80 °C (176 °F)

- LED Power: 39 W

- LED Radiant Power: 9.1 W

- LED Wavelength: 405 nm

- Power Requirements: 90–240 V, 6.0 A, 50/60 Hz, 144 W

Form Wash L

Automate SLA Cleaning with Form Wash L

Form Wash L ensures thorough cleaning of SLA 3D printed parts by automating the washing process, delivering consistently smooth and high-quality results.

After the washing cycle, parts are automatically lifted from the solvent to air dry, preventing issues such as over-soaking and warping. The integrated solvent monitor alerts you when it's time to replace the solvent, maintaining optimal cleaning performance.

Compatible with all Formlabs SLA 3D printers, Form Wash L can wash one Form 3L build platform or two Form 3 build platforms simultaneously using the included adapter.

- Quick Set-Up: Move parts directly from the printer to Form Wash L or use the basket.

- Material Compatibility: Auto-cleans parts based on selected Formlabs material.

- Thorough Cleaning: Precision agitation ensures detailed cleaning.

- Automated Wash Cycle: Parts are automatically raised out of IPA to prevent warping.

- Printer Compatibility: Form 3L, Form 3BL, Form 4, Form 4B, Form 3/+, Form 3B/+, Form 2

- Dimensions: 78.0 x 46.0 x 67.0 cm (30.7 x 18.1 x 26.4 in); Height when open: 113 cm (44.5 in)

- Weight: 56.7 kg (125 lbs) (without solvent)

- Bucket Volume: 43 L (11.4 US gal)

- Maximum Part Size: 33.5 x 20 x 30 cm (13.2 x 7.9 x 11.8 in)

- Suggested Operating Environment: 18—28 °C (64—82 °F)

- Agitation Method: Magnetically coupled impeller

- Included Accessories: Wash Bucket, Wash Basket, Electric Solvent Pump, Flexible Scraper, Scraper, Flush Cutters, Rinse Bottle, Gloves, Form 3 Build Platform Adaptor

- Power Requirements: Input (NA) 100 - 120 VAC, 50-60Hz, 1A; Input (EU) 220 - 240 VAC, 50-60Hz, 1A

- Compatible Solvents: Formlabs Resin Washing Solution, IPA, TPM, Water

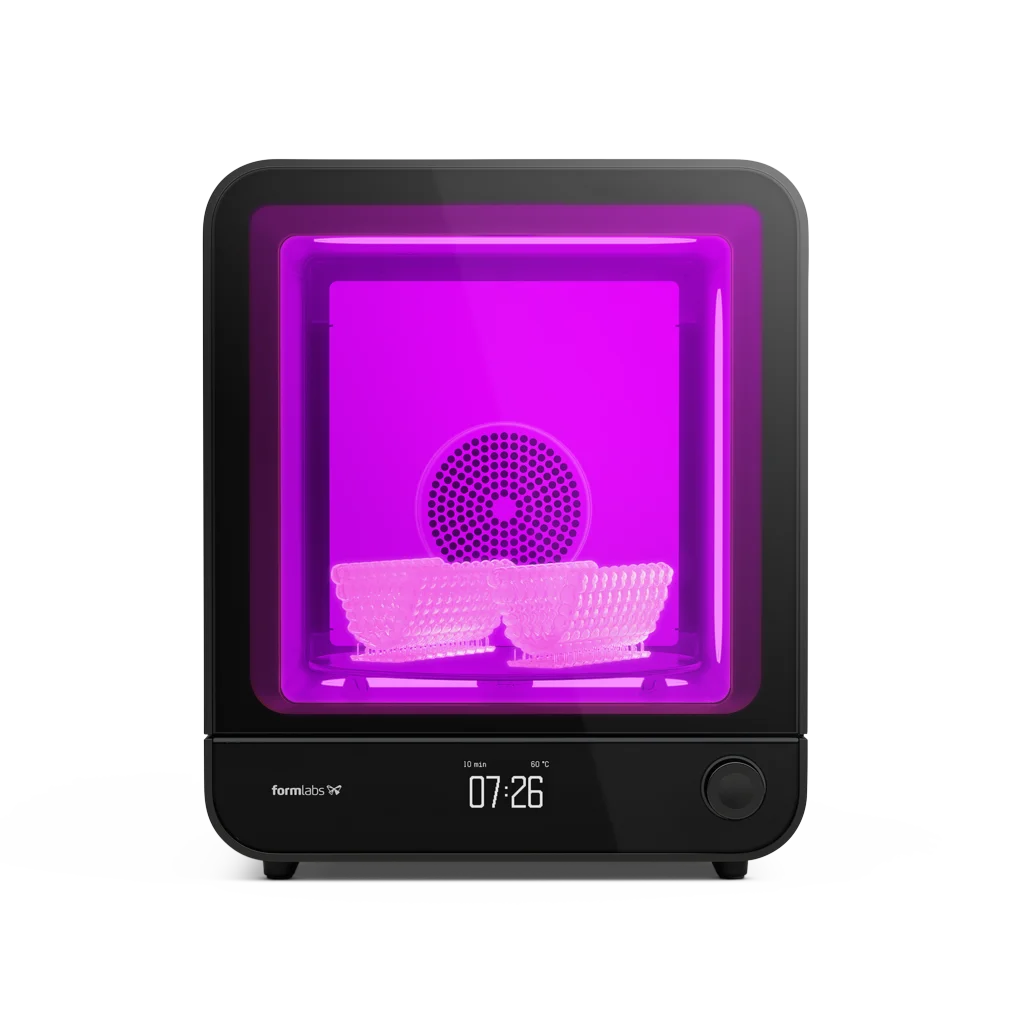

Form Cure L

Unlock Strength & Accuracy with Form Cure L

Post-curing SLA 3D printed parts enhances their mechanical properties and ensures optimal dimensional accuracy.

The Form Cure L employs dual 500W heaters and powerful UV lights, combined with a reflective inner chamber and rotating turntable, to deliver a consistent and high-intensity curing process.

Designed for both large prints and high-volume production of smaller parts, Form Cure L is fully compatible with all Formlabs SLA 3D printers, ensuring superior post-curing results across your projects.

- Advanced Heating - Preheat the chamber for optimal post-curing readiness.

- Uniform Exposure - Achieve consistent curing with a rotating turntable.

- Maximize Material Properties - Utilize default settings tailored to each material for peak performance.

- Rapid, High-Intensity Curing - Two 500W heaters reach up to 80°C in under 10 minutes, complemented by UV light modules for fast, effective curing.

- Printer Compatibility: Form 3L, Form 3BL, Form 4, Form 4B, Form 3/+, Form 3B/+, Form 2

- Dimensions: 69.0 x 54.0 x 44.5 cm (27.2 x 21.3 x 17.5 in)

- Height When Open: 69.0 cm (27.2 in)

- Weight: 24 kg (53 lbs)

- Turntable Diameter: 39.5 cm (15.6 in)

- Maximum Part Height: 32 cm (12.6 in)

- Operating Temperature: Suggested 18—28 °C (64—82 °F)

- Maximum Cure Chamber Temperature: 80 °C (176 °F)

- LED Power: 70 W

- LED Radiant Power: 36 W

- LED Wavelength: 375 nm, 405 nm

- Power Requirements: Input (NA) 100 - 120 VAC, 50-60Hz, 15A; Input (EU) 220 - 240 VAC, 50-60Hz, 8A

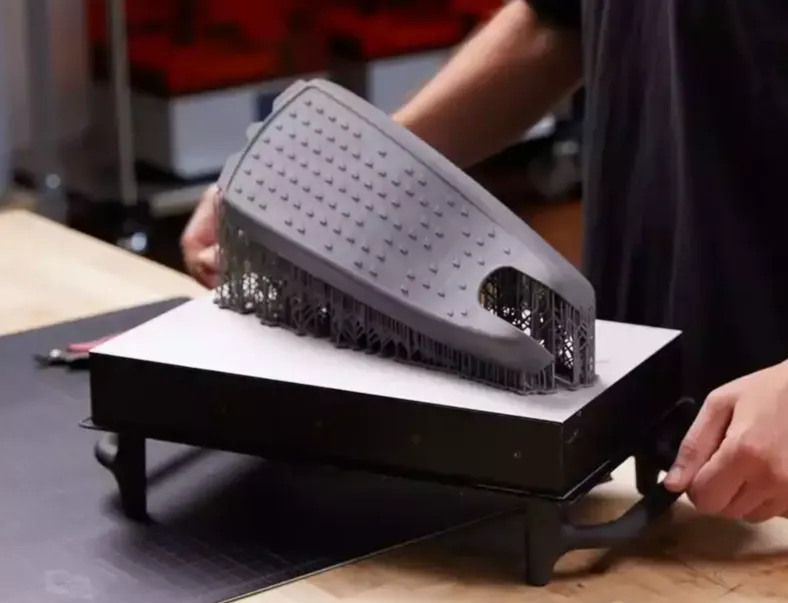

Fuse 1+ 30W

Truly Rapid SLS 3D Printing, From Print to Finish

The Fuse 1+ 30W is a compact, industrial SLS 3D printer designed for high efficiency and minimal waste. It offers exceptional print speeds and broad material compatibility, enabling rapid in-house production. With user-friendly hardware and software, the Fuse 1+ 30W streamlines every step of the process, from setup to powder recovery, ensuring maximum output and efficiency.

Build Volume

16.5 x 16.5 x 30 cm

6.5 x 6.5 x 11.8 in

Technology

Selective Laser Sintering (SLS)

- Rapid Post-Processing: Transition from print to finished parts in as little as 15 minutes.

- Fast Printing: 30W laser enables quick production of prototypes and small-series parts.

- Efficient Workflow: Hands-off setup and processing streamline the production process.

- Same-Day Prototypes: Quickly create and test prototypes within the same day.

- Durable Parts: Manufacture industrial-grade end-use parts in under 24 hours.

- High-speed printing for maximum throughput and fast turnaround.

- Rapid prototyping and production of industrial-grade, end-use parts.

- In-house manufacturing with complete design freedom.

- Ready-to-use, patient-specific, and biocompatible medical devices.

Fuse Sift

Convenient, Compact Powder Management

Our comprehensive powder management station, Fuse Sift, integrates part extraction, powder recovery, storage, and mixing into one streamlined device.

It automates the dispensing and blending of used and new powders, helping you minimize waste and maintain precise control over your powder supply.

Fuse Blast

Fully Automated Part Cleaning And Polishing

Fuse Blast is a sophisticated automated finishing solution designed for SLS parts. It efficiently removes excess powder and consistently produces professionally clean parts with a smooth, semi-gloss finish.

The Fuse Blast Polishing System ensures your parts are ready for dyeing, delivering exceptional surface quality every time.

GOT ANY QUERIES?

We are here to answer