FDM vs SLA 3D Printing: Choosing a User-Friendly FDM 3D Printer or SLA Resin Printer for Entry-Level and Professional Needs

So, you’re ready to dive into 3D printing—awesome! Whether you’re crafting a slick prototype, a custom tool, or a jaw-dropping models, picking the right 3D printer is your launchpad to success. The contenders? Fused Deposition Modelling (FDM) and Stereolithography (SLA)—two powerhouses with distinct vibes. This guide is your roadmap to choosing the perfect 3D printer for your needs, blending practical tips with a fresh, modern spin. We’re diving deep into costs, quality, ease, and even eco-friendliness to help you make a smart buy. Let’s find your dream machine and start printing the future!

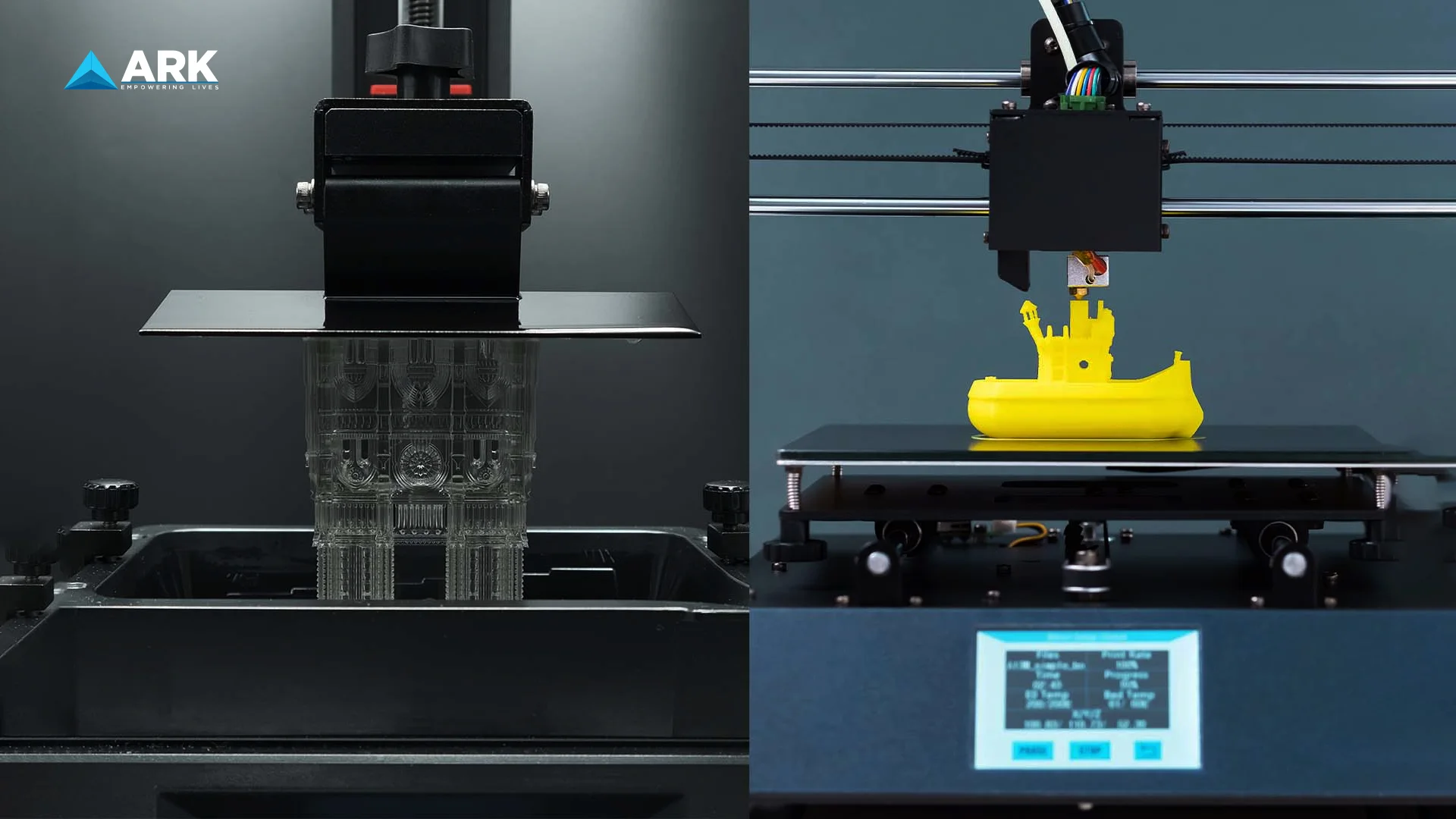

FDM vs. SLA: What’s the Vibe?

FDM 3D Printer: Think of it as a digital doodler. It melts plastic filament—like PLA or ABS—and stacks it layer by layer, like building a tower of tiny pancakes. It’s budget-friendly and versatile, perfect for all kinds of projects.

SLA 3D Printer: Picture a laser artist. It zaps liquid resin into solid shapes inside a tank, crafting parts with razor-sharp detail. It’s like painting with light—ideal for creations that need to pop.

Your choice hinges on what you’re making, how much you’re spending, and how hands-on you want to get. Let’s break it down to nail your 3D printer selection.

Head-to-Head: FDM vs. SLA Breakdown

Here’s a quick snapshot to kick things off:

Step 1: Pin Down Your 3D Printing Goals

First up: What are you building? Your project’s DNA—size, purpose, detail—shapes your choice.

FDM 3D Printing Excels When: You’re churning out sturdy prototypes, workshop tools, or big parts without breaking the bank. Think phone holders, car brackets, or cosplay props—tough enough to handle real-world use.

SLA 3D Printing Rocks If: You’re all about precision and polish. Need a dental model, intricate jewellery, or a client-ready figurine? SLA’s laser-crisp finish and fine details scream professional.

Hack It: Jot down your must-haves—durability, aesthetics, or scale—to guide your 3D printer comparison.

Step 2: Size Up Your Budget

Money talks so let’s get real about costs for your 3D printer purchase.

FDM: The wallet whisperer. Entry-level FDM printers cost as little as a new phone, and filaments are dirt-cheap—like buying snacks, not steak. Perfect for students, startups, or DIYers keeping it lean.

SLA: A premium pick. SLA printers and resins hit harder on the wallet, plus you’ll need gloves, cleaning alcohol, and maybe a curing kit. It’s a pro move if you’re chasing top-tier results.

Budget Booster: FDM lets you print more for less—tweak settings like infill to stretch filament further. SLA’s resins demand planning to avoid wasting pricey material.

Step 3: Check the Workflow Vibe

How much effort are you cool with? Your 3D printing experience depends on it.

FDM: Chill and simple. Pop in the filament, press start, and you’re golden. After printing, snap off any supports and sand if you want it sleek. It’s low-drama, ideal for beginners or busy bees.

SLA: A bit extra. You’re dealing with sticky resin, washing parts in alcohol, and curing them under UV light. It’s like crafting a gourmet dish—more steps, more cleanup, and you’ll need a ventilated spot for fumes.

Life Hack: SLA’s whisper-quiet printing won’t annoy roommates, unlike FDM’s coffee-shop buzz. Hate messes? FDM’s cleaner flow might be your jam.

Step 4: Plan for the Long Haul

Your printer’s a partner, not a fling. Think about futureproofing.

FDM: Filaments store like champs—keep them dry, and they’re good for years. FDM printers also scale up; some handle huge prints (like furniture) if you level up later.

SLA: Resins are fussier, losing mojo in 6–12 months. Buy what you’ll use soon to avoid tossing cash. SLA’s smaller build area limits big projects, so plan ahead.

Growth Move: FDM offers wild material variety—think carbon fiber, wood, or glow-in-the-dark—for future experiments. SLA’s resins are catching up with flexible or tough options, but choices are slimmer.

Step 5: Go Green (or Greener)

Want your 3D printing setup to tread lightly? Here’s the eco scoop.

FDM: Creates scraps from supports, and recycling filaments isn’t always easy. But it uses less power, keeping your energy footprint small.

SLA: Resin waste and cleaning chemicals (like alcohol) add up, and disposal needs care. It also pulls more electricity. FDM edges out slightly for eco points, but both need smart handling.

Green Tip: Try biodegradable PLA for FDM or low-waste resins for SLA to shrink your impact.

Try This: Picture Your Project

Imagine you’re designing a custom earbud case. With an FDM 3D printer, you’d spend $3–5 on PLA, print it in a few hours, and get a sturdy case that’s drop-proof but shows some lines. With an SLA 3D printer, you’d drop $10–15 on resin for a glossy, detailed case that looks store-bought—great for a pitch but fragile if tossed around. FDM’s your rugged tester; SLA’s your polished closer.

Your 3D Printer Checklist

Before you click “buy,” ask these:

Budget? Can I handle SLA’s higher costs, or is FDM’s low price my speed?

Purpose? Rugged parts for use (FDM) or stunning details for show (SLA)?

Effort? Ready for SLA’s extra steps, or craving FDM’s simplicity?

Future? Need big prints or new materials later?

Start Printing Your Vision

Choosing an FDM vs. SLA 3D printer isn’t about crowning a champ—it’s about picking your tool. FDM 3D printing brings tough, affordable parts to life for prototypes and tools. SLA 3D printing delivers sleek, detailed designs that turn heads. Either way, you’re unlocking a world where ideas become reality, fast.

At ARK Infosolutions, we’re all about fueling your 3D printing adventure. Ready to find the best 3D printer for your goals? Drop a line to us at formlabs@arkinfo.in to explore top-tier options and kickstart your journey. Let’s print something epic—one layer at a time!