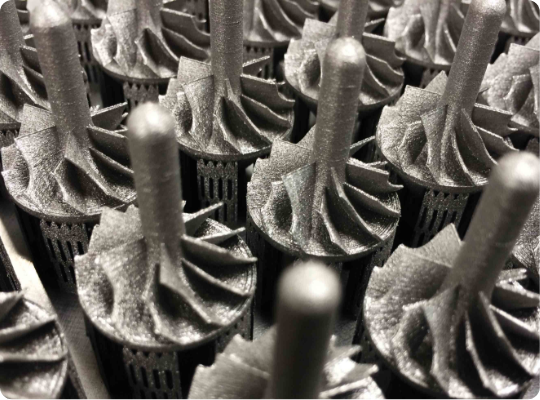

SLM SOLUTIONS "ADDITIVE ALLIANCE AGAINST CORONA"

3D Printing can make a significant contribution in the fight against the impact due to the COVID-19 virus. Let´s work together and benefit from a strong network.

SLM 125

Accurate, compact metal 3D printing with low powder volume

Benefits

Versatile, compact metal 3D printing with low powder volume

- Increased build speed with patented bi-directional powder coating

- Adaptable for research & development

- Modify system parameters according to your production needs

- Open and flexible software architecture

- Optimized gas recirculation provides for safe & cost-efficient consumption

- Closed-loop powder handling

SLM 280

Pioneer twin-laser system with automated, closed-loop powder handling

Benefits

Metal printer ideal for volume production and large prototype applications, Multiple lasers and best-in-class gas flow for demanding metal additive manufacturing applications

- Faster processing with twin-laser configurations

- Patented bi-directional powder re-coating

- Multiple laser solutions with 400W, 700W or 1000W

- 2+1 filter configuration lengthens filter life

- Safe, closed-loop powder handling

- Open system architecture for materials and parameters

- Upgraded process control

- Optimized gas flow and recirculation

SLM 500

Additive manufacturing with up to four lasers and permanent filter for demanding applications

Benefits

Four lasers and 2800w of power for demanding applications

- Twin 400W or 700W fiber lasers

- Quad laser processing

- Integrate lasers independently or in parallel

- Lower production cost for high volume metal parts with material saving and efficient closed-loop powder handling

- Increase build speeds with patented bi-directional recoating

- Adapter for higher platform temperatures

- Open software architecture & system parameters

- Optimized laminated gas flow and recirculation

SLM 800

Pioneer twin-laser system with automated, closed-loop powder handling

Benefits

Powder bed fusion with expanded build envelope and integrated automation

New possibilities for large-scale production parts

- Build envelope measuring 500 x 280 x 850 mm

- Choice of four 400W lasers, or four 700W lasers

- Integrate lasers independently or in parallel

- Integrated powder handling

- Increase build speeds with patented bi-directional recoating

- Optimized inert gas flow

- Open software architecture & system parameters

- Permanent filter module

- Customizable unpacking solutions:

- PRS 800 – for single machine operation, offers a manual entry into large-scale production

- SLM HUB – fully automated powder handling station, up to 5 systems can be modularly connected

Industry Specific Case Studies

GOT ANY QUERIES?

We are here to answer