The manufacturing landscape is undergoing a revolutionary transformation with the advent of 3D printing and additive manufacturing technologies. This article delves into the future of manufacturing, exploring the impact of 3D printing and additive manufacturing processes. Let's unravel the potential and possibilities that these innovative technologies bring to the manufacturing industry.

Transformative Potential of 3D Printing:

1. Precision Engineering:

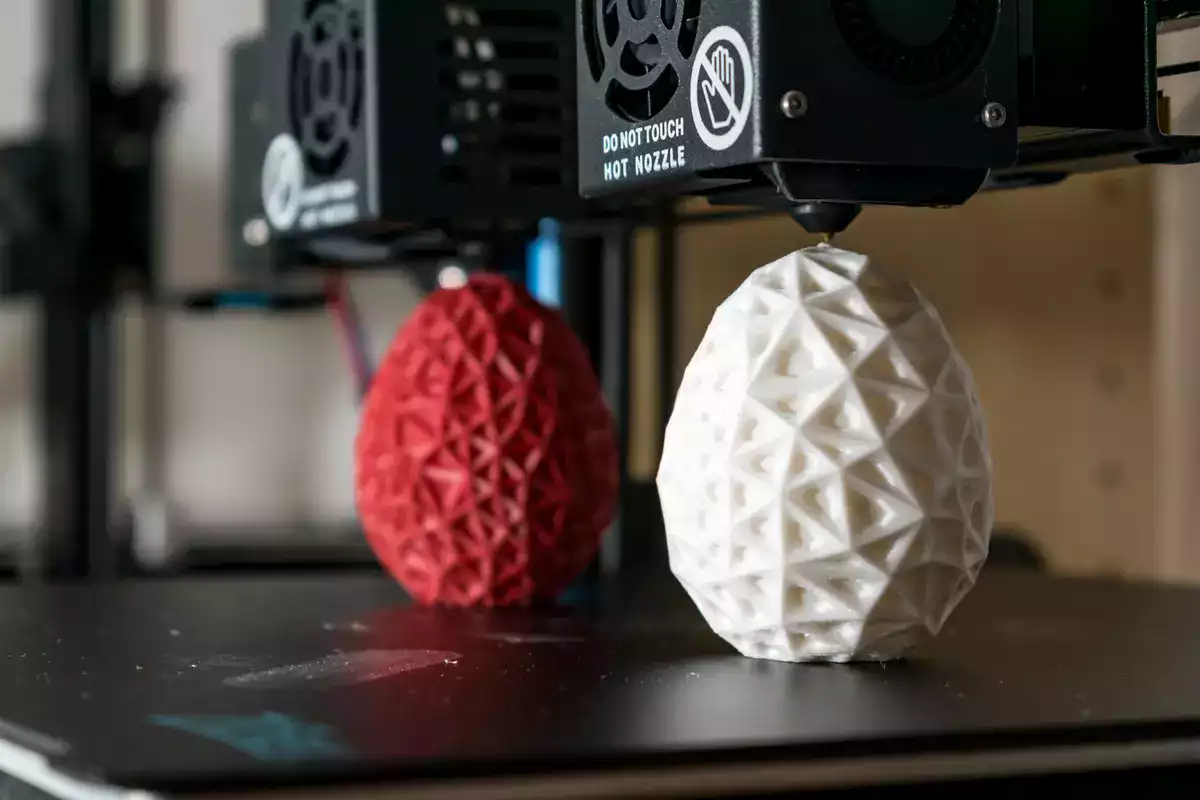

3D printing, also known as additive manufacturing, offers precision engineering capabilities that were once deemed futuristic. This technology allows manufacturers to create intricate and complex designs with a level of detail and accuracy that traditional manufacturing methods may struggle to achieve.

2. Rapid Prototyping:

One of the standout features of 3D printing is its ability to facilitate rapid prototyping. Manufacturers can quickly and cost-effectively produce prototypes, enabling them to iterate designs and bring products to market faster. This agility is a game-changer in industries where time-to-market is a critical factor.

3. Customization at Scale:

3D printing empowers manufacturers to achieve customization at scale. Whether it's creating personalized medical implants or tailoring consumer products to individual preferences, the versatility of 3D printing opens up new avenues for meeting the unique needs of diverse markets.

4. Reducing Material Waste:

Traditional manufacturing processes often generate significant material waste. In contrast, 3D printing is an additive process, layering materials precisely to build the final product. This reduces material wastage, making it a more sustainable option for environmentally conscious manufacturing.

Additive Manufacturing in Action:

Stratasys 3D Printers:

Stratasys stands as a pioneering force in the realm of 3D printing. Their cutting-edge 3D printers are renowned for their versatility and precision. From aerospace components to medical devices, Stratasys printers are at the forefront of additive manufacturing, driving innovation across various industries.

Intech's Contribution to Additive Manufacturing:

As a leading player in the additive manufacturing space, Intech has established itself as a key contributor to the future of manufacturing. Intech's Metal 3D printers bring advanced capabilities to the table, offering manufacturers the tools they need to embrace additive manufacturing with confidence.

The Future Landscape:

1. Industry 4.0 Integration:

The integration of 3D printing and additive manufacturing aligns seamlessly with the principles of Industry 4.0. The interconnectedness of smart technologies, data analytics, and automation finds a natural ally in the precision and efficiency of additive manufacturing processes.

2. Supply Chain Resilience:

The decentralized nature of 3D printing allows for distributed manufacturing, contributing to enhanced supply chain resilience. Manufacturers can produce components on-site, reducing dependency on centralized production facilities and mitigating the impact of supply chain disruptions.

3. Expansion of Material Options:

As research and development in additive manufacturing progress, the range of printable materials continues to expand. From metals to bio-compatible polymers, the versatility of 3D printing materials paves the way for innovations in diverse industries, including healthcare, aerospace, and automotive.

Conclusion:

The future of manufacturing is intricately tied to the transformative potential of 3D printing and additive manufacturing technologies. Stratasys and Intech, as leading contributors to this future, exemplify the cutting-edge capabilities and advancements in the field. The precision, rapid prototyping, customization, and sustainability offered by these technologies position them as catalysts for a new era in manufacturing. As Industry 4.0 integration accelerates and the supply chain becomes more resilient, the landscape of manufacturing is set to evolve, driven by the endless possibilities unlocked by 3D printing and additive manufacturing.